- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

nyloflex® Plate Making Equipment

nyloflex® plate making and processing equipment are combination or single units, comprising exposure, washer, light finisher, dryer, and cutting table. XSYS offers all you need to make a print-ready flexo printing form – flat or round – solvent or water or thermal:

nyloflex® equipment and ThermoFlexX are proven in combination with nyloflex® photopolymer plates & sleeves. nyloflex® plates can be used with all laser systems suitable for imaging flexo printing plates.

nyloflex® Xpress Thermal System

For the processing of thermal nyloflex® plates, XSYS Flexographic Products offers the nyloflex® Xpress Thermal Processor. It compares innovative machine design with premium technology, manufactured in the U.S.

The nyloflex® Xpress Thermal Processing System is more than just a processor. It is a program that is simple, clear, and transparent to deliver precise results every time. Learn more about the whole nyloflex® Xpress system.

nyloflex® Plate Processing Equipment

nyloflex® equipment for solvent processing of flexo plates is available in different sizes for different plate formats. It is available for narrow web, mid web, and wide web applications. The most compact unit is the nyloflex® Combi FII with a maximal plate format of 860 x 660 mm (33.9″ x 26.0″) and one of the largest units is the nyloflex® Dryer FIV with a maximal plate format of 1250 x 1600 mm (49.2″ x 63.0″).

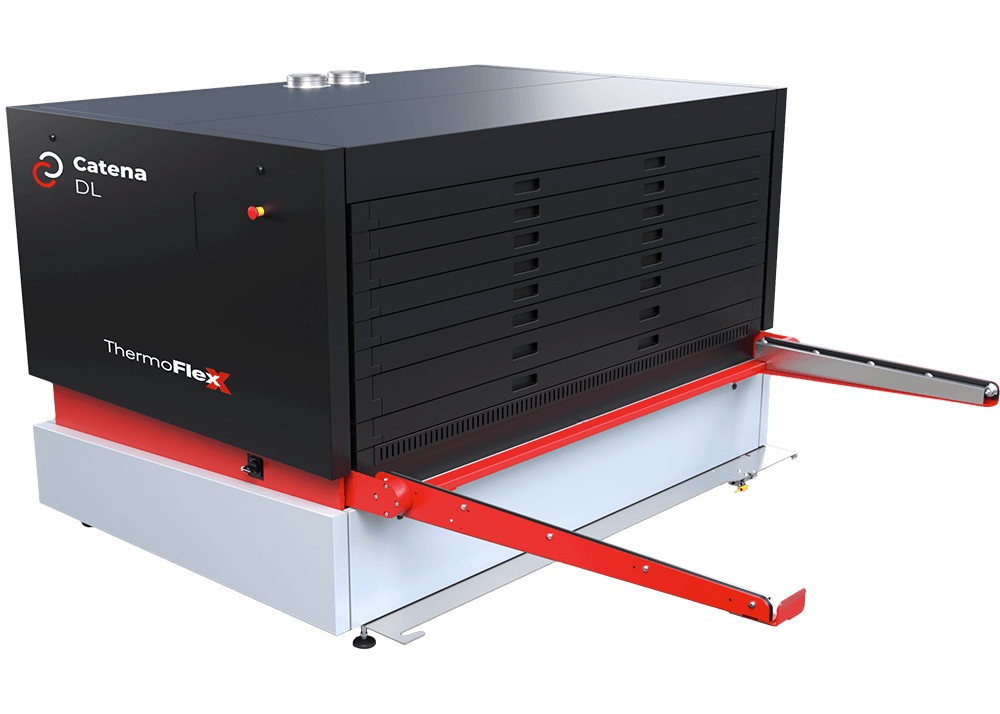

ThermoFlexX Catena Plate Processing Equipment

ThermoFlexX Catena equipment help you streamline your processes for a more efficient workflow. This plate processing equipment automates the production with a user-friendly operating system that allows easy plate loading as well as access to production data for all modules, giving you total control to keep everything aligned the way you need it to. Explore Catena products here.