Description

Peristaltic tube pumps are designed to handle more viscous inks, adhesives and coatings, ideal for sheer sensitive liquids. Downtime is kept to a minimum by simply changing the hose in the Delrin pump head.

Peristaltic tube pumps are designed to handle more viscous inks, adhesives and coatings, ideal for sheer sensitive liquids. Downtime is kept to a minimum by simply changing the hose in the Delrin pump head.

Model PN4 Control Panel

These pumps are supplied with the following specifications: air gear motors (intrinsically explosion proof), non-explosion proof inverter drive models, and electric explosion proof mechanical gear units. All models can be supplied with reversible feature to drain ink stations and enclosed doctor blades. Variable speed allows controlled ink flow.

For the inverter drive units, we provide a convenient control panel that allows you to simply plug the pump in and control the speed and direction by a simple switch mechanism. All inverters are programmable to allow the operators to get the exact flow they need.

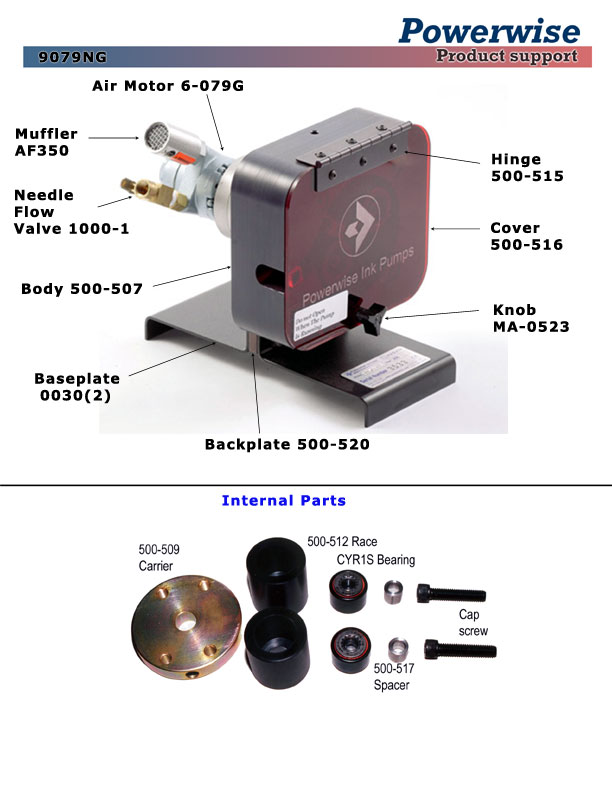

AIR DRIVEN PERISTALTIC TUBE PUMPS

This specification is for USA & European Market

Suitable for both hazardous & non-hazardous areas.

Standard Flexographic and Gravure ink applications

Geared Air Motor

Lubricated Air 25 – 100 PSI Range Required

Adjustable speed range 0-350 RPM

Flow Rate 0 – 2.5 GPM (0 – 9.35 LPM)

This pump will handle high viscosity fluids and is ideal for heavy inks and adhesives.

More Pictures of this pump

Picture 1

Loading the Tube data sheet (Link)

General notes concerning the tube.(Tube Notes)

Videos

Tubing Selection & Use

Loading the Tube on a peristaltic Pump

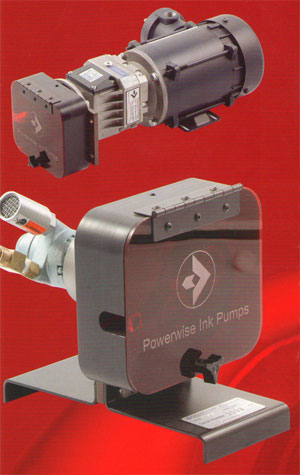

NON EXPLOSION ELECTRIC DRIVEN PERISTALTIC TUBE PUMPS

This specification is for USA & European Market

Suitable for non-hazardous areas.

Standard Flexographic and Gravure ink applications

110/220 Single Phase Voltage requirement for Inverter

Adjustable speed range 0-350 RPM

Forward/Stop/Reverse Switching

Flow Rate 0 – 2.5 GPM (0 – 9.35 LPM)

This pump will handle high viscosity fluids and is ideal for heavy inks and adhesives.

More Pictures of this pump

Picture 1

Picture 2

Loading the Tube data sheet (Link)

General notes concerning the tube.(Tube Notes)

Videos

Tubing Selection & Use

Loading the Tube on a peristaltic Pump

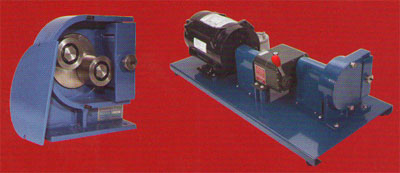

EXPLOSION ELECTRIC DRIVEN PERISTALTIC TUBE PUMPS

This specification is for USA & European Market

Suitable for hazardous areas.

Standard Flexographic and Gravure ink applications

0.5HP/037Kw Explosion proof Motor 230/460.3.50/60 Voltage

Adjustable speed range 0-250 RPM

Forward/Reverse Using Hand-wheel

Flow Rate 0 – 2.5 GPM (0 – 9.35 LPM)

This pump will handle high viscosity fluids and is ideal for heavy inks and adhesives.

More Pictures of this pump

Picture 1

Picture 2

Starting & Adjustment (Link)

Atex Instructions (Link)

Loading the Tube data sheet (Link)

General notes concerning the tube.(Tube Notes)

Videos

Operating the Pump

Tubing Selection & Use

Loading the Tube on a peristaltic Pump

Powerwise peristaltic tube pumps are ideal for corrosive, abrasive and shear sensitive solutions. The pump design eliminates all contact of pump parts with the materials being transferred. A flexible tube passes through the pump head and is alternately compress by a set of rollers, resulting in the flow of material through the tube. We have small flow rated pumps to very large flow pumps, as well as single head and double head pumps available. This versatile pump can be used throughout the printing plant.

- Quick and easy changeover

- Variable flow control

- Reversible

- Positive displacement

- Air or Electric

- Air driven mixers

- Tubing, choose from Santoprene, Prothane II, Silicone or Neoprene. (Others are available)

- Pump Carts and stainless steel tanks and lids

- Quick disconnect fittings

Which model is right for your application? Check your required viscosity range, press size, ink type and flow. Remember peristaltic pumps do not agitate the ink in the container and many printers use a small Powermix agitator.