- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

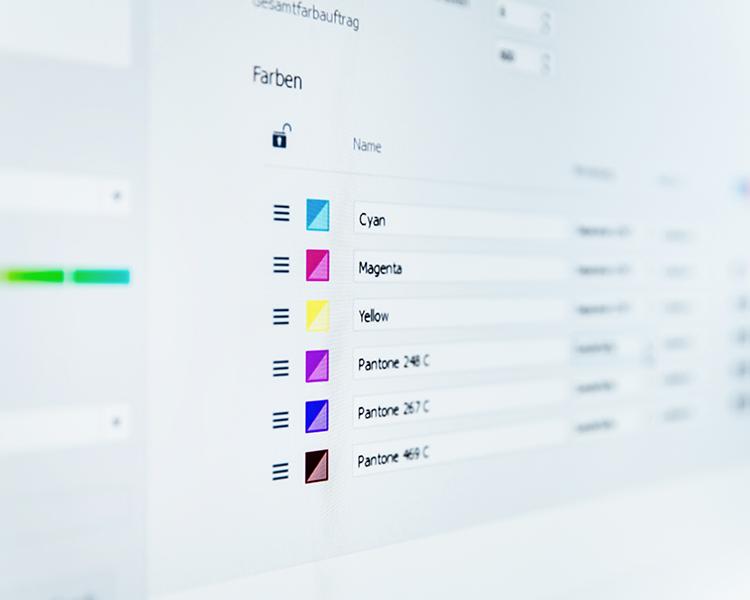

GMG Color Management Solutions

GMG’s color management solution ensures that print results exactly match the color specified. Regardless of the print process or the substrate printed on. Experts of the print industry, creative agencies as well as brand owners from some of the biggest consumer brands count on GMG. They tirelessly perfect solutions in close collaboration with our customers to ensure their globally leading proofing- and color management software solutions remain the standard.

GMG ColorProof

GMG OpenColor

GMG ColorPlugin

GMG ColorServer

GMG ProofControl

GMG ProofMedia

GMG ColorCard

Efficient and reliable proofing in line with international standards

In order to accurately predict a print result it is paramount to use a reliable proofing solution. For all parties in a print production – clients, agencies, photographers, post-production, prepress specialists and printers – to communicate reliably, it is essential that they work within accepted standards. GMG ColorProof sets the standard for digital proofing globally.

Consistent proof results anytime, anywhere

GMG ColorProof is at the heart of a powerful system integrating digital proofing devices and GMG ProofMedia that simulate the final print results of a printing press. GMG’s innovative calibration concept ensures stability and reliability across a range of proofing- and measuring-devices in multiple locations.

Plug & Proof

GMG ColorProof comes pre-loaded with color profiles for all standards, ensuring a ‘no hassle’ setup. Simply select your printer, calibrate and proof. Thanks to the pre-loaded color profiles, creating color-accurate reference proofs is effortless.Consistent results across multiple locations

Thanks to GMG ColorProof GO and the remote proofing function, it’s simple to achieve the same print results wherever your printer is located – in the room next door or in another country. Controlled via a browser, all proofers on the systems are easily controlled and managed from anywhere in the world.

Reliable packaging printing

Due to the wide range of printing processes and substrates in packaging printing, individual adjustments are part of the daily routine. The combination of GMG OpenColor and GMG ColorProof makes the creation of customer-specific standards unbelievably easy.Proofing for specific applications

With GMG DotProof, the screen angles, screen ruling and dot shape as well as color of a proof can be simulated accurately. Print issues such as register misalignments or the wide variety of printing substrates in flexo printing can also be simulated with GMG FlexoProof.

Powerful color management for packaging printing

In packaging printing, different printing technologies, various media types and printing conditions often lead to deviations from industry standards. This poses a challenge for the entire production process to efficiently achieve a consistent brand image. GMG OpenColor uses a spectral conversion technology at its core, which precisely predicts the overprinting of process and spot colors. The patented technology allows you to avoid lengthy correction loops on press before printing and makes creating custom profiles positively simple.

Precise simulations with spectral data

Our patented conversion technology enables color-accurate simulation – even without test charts. In addition to spectral color data, printing process, substrates and even ink sequence are taken into account. If a parameter changes, a profile can be quickly calculated without the need to run a new proof.

All colors in one place

With our central data management philosophy and interfaces to common color databases, color profiles are created quickly and effortlessly. Even, conversions in PDF editors are achieved with just a few clicks. Data mangement in this centralized system is safer, easier and more efficient. Because all profiles used for proofing or color conversion are created from the same source data.Continous or halftone proof?

In combination with GMG ColorProof, multicolor proof profiles are dynamically calculated using the colors assigned in the print file. Potential problems such as moirés and incorrect trapping settings can also be made visible in advance using halftone profiles.

One foundation for proof and color separation

GMG OpenColor creates proof profiles as well as separation profiles. These profiles transfer effortlessly to GMG ColorServer and GMG ColorPlugin, allowing the use of the most sophisticated color transformation tools to work seamlessly with Adobe Photoshop. Extended color space projects and the replacement of CMYK channels with specials in Photoshop is now quick and simple. GMG OpenColor delivers the flexibility you wish for and the reliability you need.Multiple award-winning solution

"This product gives printers the freedom to mix their own ink sets and make color separations using the maximum color space. GMG OpenColor produces accurate colors in proof and print." - Conclusion of European Digital Press Association Committee, 2017 | GMG OpenColor: Winner of EDP Awards

Quick, accurate and safe image conversions in Adobe Photoshop

In packaging, print data processing in Adobe Photoshop often requires the replacement of a process color or even a channel extension of a CMYK image with one or more spot colors. Achieving the customer’s exact color specification using manual conversion can be very time-consuming even for the most experienced operators. GMG ColorPlugin achieves the required result with a few simple clicks: from accurate color conversion into the required color space, efficient under color removal (UCR/GCR) to the most flexible image separation.

Working with spot colors in Adobe Photoshop couldn’t be easier

In packaging printing, image data is often separated using spot colors. GMG ColorPlugin enhances Adobe Photoshop by automating this process. It also extends the color space to include special inks, making the process of jobs printed with specials easier and much more predictable.

Accurate predictions

The approval process for images and color graphics can be complex and time-consuming. Our soft-proof solution GMG ColorPlugin allows the operator to preview the job accurately on-screen using the enhanced preview function in Adobe Photoshop. This allows quick and accurate approval saving time and money on proofing steps.Greater print stability

Exchanging or removing individual channels for more stability in printing is possible with features like ChannelChanger and ChannelRemover. Complete images, masked areas or layers can be used to convert all or parts of a job into the desired color space or adjusted to the chosen print process.

Optimized for flexo printing

Problematic areas for flexographic printing, such as the first printing dot, can be identified with MinDot Preview and optimized for printing with MinDot Adjust. This ensures that even images with fine detail are printed accurately and banding is minimized.The complete solution for color conversion

GMG ColorPlugin allows you to use the superior GMG MX technology in Adobe Photoshop. Profiles created in GMG ColorServer, GMG InkOptimizer or GMG OpenColor can effortlessly integrate into your image processing workflow.

Automatic conversion to the output color space

Different printing conditions, substrates or printing standards around the world can make it difficult to ensure a consistent brand image. That’s why it’s crucial to introduce an automated step for color-accurate conversion. GMG ColorServer automatically converts RGB, CMYK and mixed data into an industry-standard or custom output color space using our industry-leading MX technology.

Visibly better: MX technology from GMG

With GMG ColorServer, your data can be made print ready in an instant. GMG’s MX technology – integrated into GMG ColorServer – produces the highest quality color space conversions. The technology preserves the black channel, stabilizes color and achieves an unparalleled shadow definition for consistent and visibly superior results unmatched by any other solution on the market.

Save ink with GMG InkOptimizer

GMG InkOptimizer helps save up to 20% of ink by increasing the amount of black in the separation and by reducing CMY. This form of under color removal stabilizes the grey balance and optimizes the entire printing process. The result is a more stable print run and better quality at a significantly reduced cost.Your digital printing assistant - GMG SmartProfiler

The fully integrated GMG SmartProfiler allows users to calibrate and recalibrate digital and large format presses with step-by-step guidance. The creation of custom color profiles is quick and easy to perform, ensuring the elimination of ‘guesswork’ when it comes to more complex print jobs.

In safe hands – even in the most challenging print conditions

Changing substrates, different print parameters or the use of spot colors call for customized data conversions. In combination with GMG OpenColor, specially created separation profiles can automatically import into GMG ColorServer to ensure a seamless and simple process.Automation and performance

GMG ColorServer helps streamline pre-press noticeably. Its client-server architecture distributes the process load automatically. Workflow integration into third party systems is easily achieved via an API interface.

For quick and easy verification of digital proofs

With GMG ProofControl digital proofs can be verified ensuring they comply with industry standards such as FOGRA standard. With this verification a digital proof is upgraded to a contract proof. Because the manual measurement of a color control strip is time intensive GMG’s automated solution is clearly a benefit. GMG ProofControl is not only accurate but also unbeatably efficient.

Plug & Verify

GMG ProofControl includes all international standards as well as common control strips. This makes it easy to check whether a proof is within an industry-standard tolerance range before it’s verified with a proof label.

The green check

Color accuracy is measured and reliably documented. The process is incredibly simple. Print, measure the control strip and verify. When the green checkmark appears, the proof is verified. The self-adhesive label is applied to the proof to verify it as a contract proof. On printers with built-in measuring devices, proof verification can even be automated.Flexible packaging printing

Individual adjustments are part of day-to-day business in packaging printing and therefore require special quality control. GMG ProofControl enables you to create and save custom standards allowing you to verify jobs based on your clients’ agreed standards. This ensures consistent results and happy clients.

High-performance media for the most demanding color communication

Reliable proof substrates are crucial for the production of contract proofs. The smallest production inconsistencies, differing surface structures or unstable drying behaviours of proof media can lead to visual differences in color appearance. Aside from proofing device, software and color profiles, the proof media plays a key role in achieving consistent proof results. This creates a demand for high-performance substrates that are available worldwide produced to unmatched quality standards.

The key to reliable accuracy – GMG Proofing Solution

A reliable proofing system is key to achieving color-accurate results. GMG ProofMedia plays a crucial role in this closed system of GMG software, high-end proofing devices and GMG color management know-how.

GMG ProofMedia Premium – color accuracy without compromise

Highest product quality, global availability and superior light fastness mean that GMG ProofMedia Premium enables the proofing of all industry printing standards. It is for that reason that the GMG back print is accepted as a seal of approval, and together with GMG ProofControl it ensures a proof meets the industry’s highest quality standard.GMG ProofMedia Studio – the look and feel of the final print result

The feel of GMG ProofMedia Studio range is particularly convincing and unique: When color-accurate reference proofs are required to resemble the final printing stock, the GMG ProofMedia Studio range is the substrate of choice.

Color accuracy – even under light containing UV

When paper is examined under light containing UV rays the difference between substrates containing Optical Brightening Agents (OBA) and those without are apparent. Because printing papers often contain OBA it is paramount that the proofs are also produced on proof paper with Optical Brightening Agents. That’s why the GMG ProofMedia portfolio includes substrates containing OBA to ensure a visual match of proof and production print when viewed under UV light.Sustainable and climate neutral

At GMG, we strive to minimise resources during production and reduce CO2 emissions. Our GMG ProofMedia Papers carry the FSC® certificate, and we also cooperate with ClimatePartner® to reduce the carbon footprint of GMG ProofMedia production.

Binding color communication for the packaging industry

When brands demand accurate color reproduction of their brand colors they use ink drawdowns during the approval process. Until now, these ink drawdowns, or color cards, were manually created – needless to say, that this was an extremely time-consuming process. GMG ColorCard is the digital innovation that automates the manual, labor-intense process using spectral data from the ink lab. It consistently produces precise color swatches for any spot color.

Color card production: time is money

A clear advantage of digital flexibility: Every time a color card has to be reproduced, the result is identical, making it easy to manage production costs. High cost of manual ink drawdowns is a thing of the past – the future is digital.

Quick and easy to use

Compared with conventionally produced ink drawdowns, results with GMG ColorCard can be achieved significantly quicker with time savings of up to 90%. The smart solution for your accurate color communication is very easy to use and does not require specific know-how.Identical references for all process partners

Accurate proofs, predicting exactly what a brand color will look like on the chosen substrate, are essential to a smooth print production. Communication between all stakeholders at pre-press stage depends on it. Thanks to the different color card layouts, it is even possible to accurately simulate agreed production tolerances.