Description

HYBRID Software’s CLOUDFLOW workflow, iC3D, PACKZ and STEPZ editors, and print quality solutions offer a unique set of advantages that include native PDF workflows, enterprise cloud solutions, scalable technology with low cost of ownership, and direct integration with leading MIS solutions and output devices. These products are used by thousands of customers worldwide in all areas of prepress and print, including labels and packaging, folding cartons, corrugated, wide format and digital printing. HYBRID Software is a subsidiary of Hybrid Software Group.

Learn More

>> Download the Hybrid Software Brochure

PACKZ

CLOUDFLOW

Patchplanner

iC3D

The only native PDF editor for all of your packaging prepress needs

![]() PACKZ is the comprehensive PDF editing software for efficient prepress processes, including native PDF editing, step and repeat, and VDP. PACKZ shifts prepress production into a higher gear with the unique blend of automated actions – Pactions, and dedicated prepress tools. With its editing- and quality assurance-functions, the professional PDF editor makes designs print-ready for any printing process.

PACKZ is the comprehensive PDF editing software for efficient prepress processes, including native PDF editing, step and repeat, and VDP. PACKZ shifts prepress production into a higher gear with the unique blend of automated actions – Pactions, and dedicated prepress tools. With its editing- and quality assurance-functions, the professional PDF editor makes designs print-ready for any printing process.

PROFESSIONAL PDF EDITOR

- Designed for Labels & Packaging

- Native PDF, without any conversion

- Multi Platform Solution running on OS-X and Windows and in any browser

- 64-bit multi-processing and multi-threading

TRAPPING

- Unmatched speed and quality

- Single-click application

- Interactive and automatic,using the same technology

- Global or on selected areas

- Handles small gaps

STRUCTURED ASSETS

- Separation handling

- Fonts and text

- Images and graphics

- Barcode creation and recognition

- Object-based screening

LIVE OBJECTS

- Intelligent marks and info panels

- Database-enabled

- Connect Live Objects to document content

- Dynamic positioning

KEY VALUES

- Modern architecture

- Ease of use

- High performance

- Built for Labels & Packaging

- Downloadable and one-time activation

A private Production Workspace for your critical graphics production

![]()

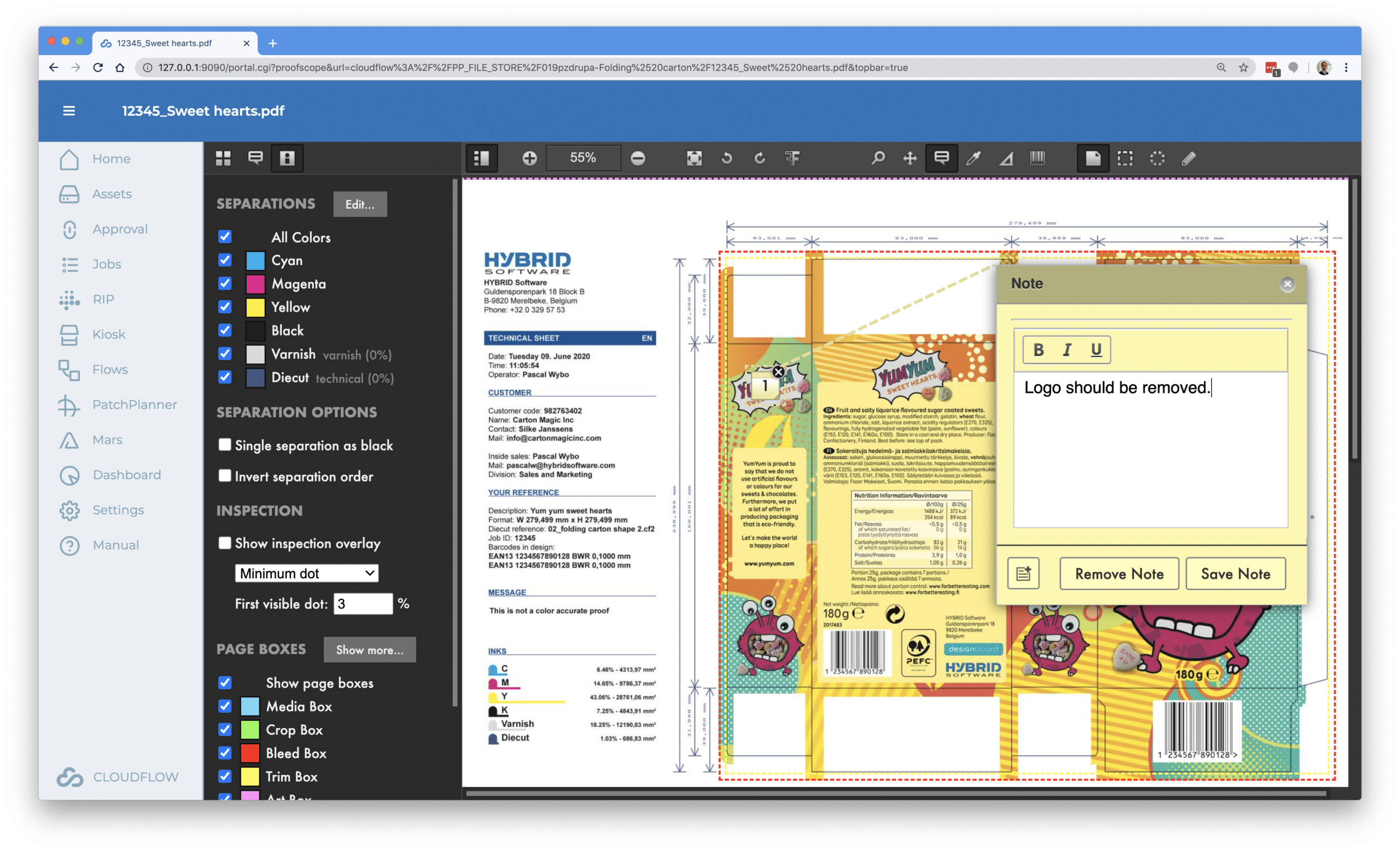

CLOUDFLOW is a compact, modern, and modular system for running automated graphics production workflows in a private computing cloud.

All CLOUDFLOW interfaces are developed in HTML5, so workflows can be controlled from any web browser or computing tablet. To keep up with customer demands, many print service providers have multiple file servers or even multiple production locations, which can make it difficult to track digital assets and balance production workloads. But CLOUDFLOW solves this problem by managing all assets and production within a private printing “cloud”, where they can be accessed from any location through an intuitive browser interface.

The heart of the CLOUDFLOW system is the CLOUDFLOW Workspace. It provides user security, file management, and total control over all workflows and production.

Many optional modules are also available to provide additional functionality for CLOUDFLOW users:

– WORKSPACE: The foundation of any CLOUDFLOW configuration. A central web-based database for all CLOUDFLOW applications.

– PROOFSCOPE: Turnkey solutions for soft proofing and collaboration. A true HTML5 viewer, no plug-ins required.

– PACKZFLOW: Prepress automation based on native PDF files with unmatched speed!

– RIP: Fast, powerful embedded RIP

– JOBS: Present job information in a graphical user interface.

– DATALINK: Connectivity and data collection that is compatible with all SQL databases.

– COCKPIT: Process management application for print production of labels and folding cartons.

– SHARE: Multi-location service for files and licenses over regular internet instead of dedicated lines.

– 3D: Workflow automation for 3D generation and viewing.

CLOUDFLOW is also compatible with any RIP or output device that you already own, and it is designed for ease of use. With today’s tight deadlines, your customer service reps (CSRs) are a critical part of the production workflow, and CLOUDFLOW enables them to collaborate with customers and prepress to meet your customers’ deadlines!

Flexo Plate Mounting Workflow for the Corrugated Industry

Patchplanner takes a PDF digital design file and optimizes the layout of the printed areas as individual elements, enabling a much smaller plate to be used than the actual size of the job. The software can then be used to control very accurately automatic cutting of the plate and repositioning of the parts on to a plastic carrier.

Flexo plates are very expensive and anyone operating in a pre-press department will immediately see the attraction of Patchplanner. When producing something like a corrugated box, it is not unusual for only a tiny area to need to be printed even though the box itself may be large. Until now a great deal of manual work has generally been required in order to avoid using large flexo plates.

What Patchplanner does is to separate those printed elements in the design file and relay them so they take up the least amount of space. This data is then used to expose the smallest plate possible using an imager such as a ThermoFlexX. We can then send the information to a cutting table, for example, a Zund machine. Patchplanner software will control the cutting pattern, resulting in fast and accurate cutting.

The plate would then be reassembled on to a plastic carrier ready for the printing press. The high level of automation offered by these systems, combined with their speed and precision, makes this an extremely cost effective method of producing flexo plates for this sort of job.

Inspiring 3D creativity for label and packaging designers

The all-in-one design tool that gets brands to market faster

The all-in-one design tool that gets brands to market faster

If you’re at the cutting edge of CPG supply and demand, you know all about balancing consumer tastes and market forces with the reality of ROI. When it comes to packaging, you need to source the right skills at the right time to ensure a smooth transition from concept to shelf in the shortest possible timeframe.

Better, faster, more versatile

At iC3D Software we believe we offer the unique capability – in iC3D – to tackle head-on the issues you face. Whether your products require carton, glass, cans, flexible packaging, labels or shrink-wraps, iC3D produces fast, accurate and photorealistic 3D visuals and prototypes on-the-fly, and ready for print.

The iC3D all-in-one package allows your designers to give full rein to their creative instincts and allows you to innovate with your brand. It offers the tools and the opportunity to review, bench test, troubleshoot and refine, to get timely buy-in from stakeholders and market.

The results speak for themselves: our users report getting their new packaging designs to market up to 80% faster.

Key benefits of iC3D:

• Faster time product Wto market

• Easier collaboration and sign-off

• Lower third-party costs

• In-store competitive visualizing

• Greater innovation potential