Description

Tesa offers a comprehensive assortment of plate mounting tapes with foam, film, or cloth backings to fulfill all flexo printing needs.

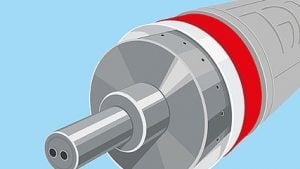

Foam Plate Mounting Tapes

tesa Softprint® plate mounting tapes with high-quality foam backings for the highest demands in flexographic printing.

Increasing demands on print quality combined with high levels of process efficiency call for specifically tailored plate mounting tapes.

Increasing demands on print quality combined with high levels of process efficiency call for specifically tailored plate mounting tapes.

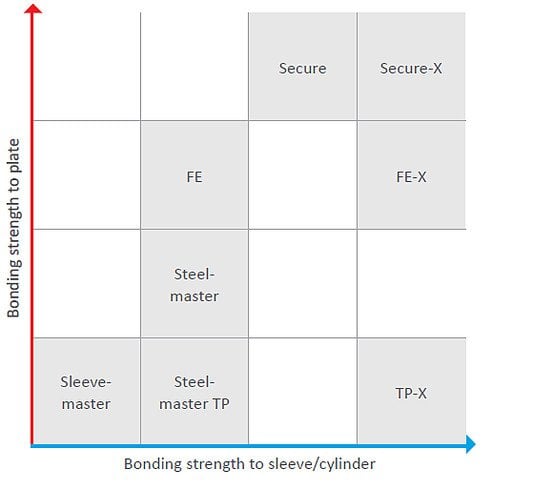

The tesa Softprint® assortment provides distinctive product lines for flexo printers to fulfill any requirement.

Depending on your process requirements, the product matrix will help you find a suitable product line from our tesa Softprint® plate mounting assortment.

Historically, foam plate mounting tapes were divided into two thickness categories: 380 μm / 15 mil for label printing (narrow web) and 500 μm / 20 mil for flexible packaging printing (wide web). Nowadays, customers decide individually which category offers the most benefits for their processes.

The tesa Softprint® assortment offers both thickness categories at an equally high level of quality in terms of print results and adhesive properties.

Learn More about Foam Plate Mounting Tapes

- Discover all tesa Softprint foam plate mounting tapes by hardness, adhesive properties and applications on tesa’s website

- Download Brochure: tesa Softprint® Plate Mounting Solutions for Flexographic Printing

Film and Cloth Plate Mounting Tapes

tesaprint® plate mounting tapes with film or cloth backings are used whenever a cushion is not required.

As part of tesa’s comprehensive assortment of plate mounting tapes, they offer incompressible tapes with film or cloth backings, used whenever a cushion (through a foam tape) is not required.

These tapes can be used in a variety of different print jobs, for example, flexo printing of corrugated board (postprint), flexo printing of film with compressible sleeves, letterpress printing of labels, or dry offset printing of cups, to name but a few. Our dedicated sales team will assist in choosing the most suitable tape for your process needs.

The tesaprint® assortment offers:

- Reliable adhesion properties, tailored to the specific requirements of the application

- Different film and cloth backing materials, ensuring a range of required product thicknesses with stable and easy tape application

- Optimized release liners, promoting easy application and ideal handling

Learn More about Film and Cloth Plate Mounting Tapes

- Discover all tesa Film and Cloth Plate Mounting Tapes by hardness, adhesive properties and applications on tesa’s website

- Download Brochure: tesaprint® Plate Mounting with Incompressible Tapes

Technology

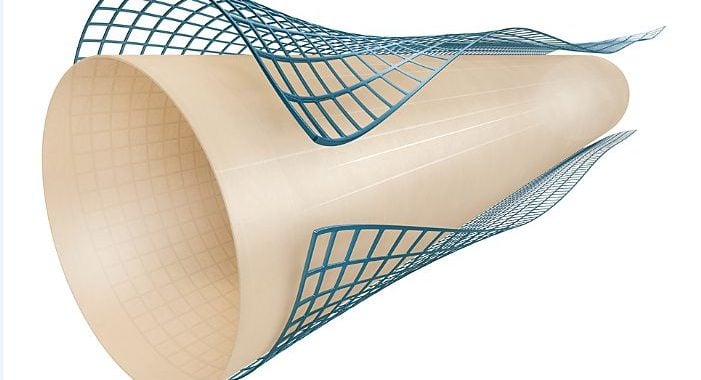

FLEX Design: For thin-walled and scratched sleeves

The flexible packaging industry is continuously working to increase productivity on the shop floor level. tesa supports this objective with the introduction of the Softprint® FE-X product line, combined with the new FLEX Product Design for maximized efficiency.

Use of Thin-Walled Sleeves

Product Feature

More flexibility in the horizontal direction, which compensates for differences in the sleeve circumstance during the mounting process onto thin-walled sleeves.

Customer Benefit

- Better tape bonding on thin-walled sleeves

- No press downtime

Use of Scratched Sleeve Surfaces

Product Feature

Alligned combination of a more flexible product design and specially-engineered adhesive on the sleeve side, achieving better bonding on inconsistent surfaces.

Customer Benefit

- Better bonding on inconsistent sleeve surfaces

- No press downtime

Benefits of tesa Softprint® FE-X Adhesives

tesa Softprint® FE-X plate mounting tapes don´t just hold down plate edges effectivity during standard conditions. Engineers have developed a plate mounting tape which also offers the best plate bonding during in press cleaning with solvents and at high temperatures and humidity. Furthermore, to optimize the print job preparation, the plate side adhesive of tesa Softprint® FE-X comes with a non-tacky surface characteristic to mount multi-color jobs faster into register. These benefits make tesa Softprint® FE-X simply productive for every printer!

Benefits of tesa Softprint® Foam Quality

The smart tape production process leads to more intact foam cells for better cushioning and resilience over time – providing excellent print quality.

Furthermore the combination of tesa Softprint tapes with the latest plate technologies and high quality printing presses allows the best print quality for combination motifs when selecting only one foam hardness. This enables printers to reduce process complexity and offers more standardized print production.