- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

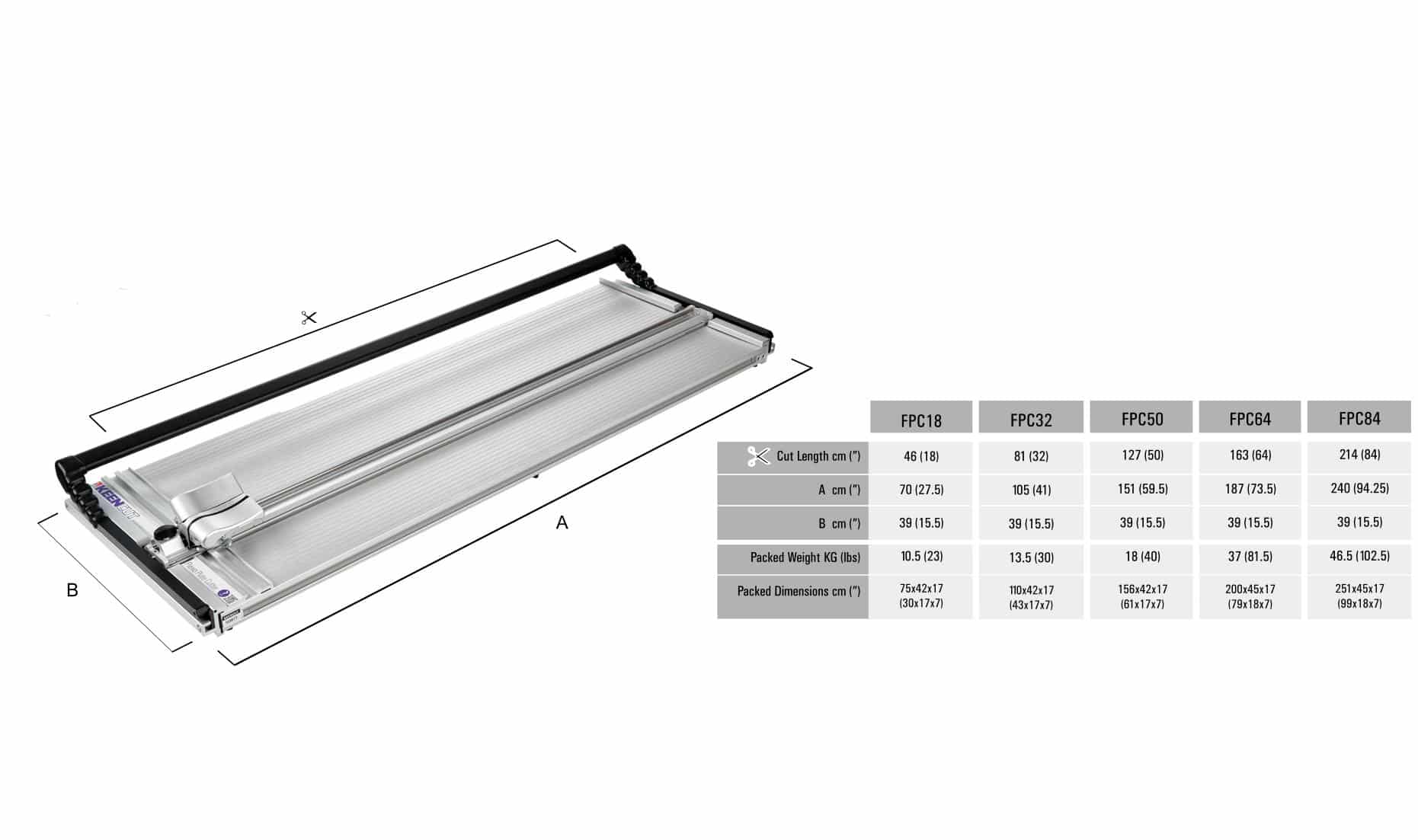

Keencut Flexo Plate Cutters

The world’s finest cutting machines …

At Keencut we guarantee that every cut is a perfect cut. We use our market-leading expertise and superior manufacturing quality to create safe, accurate and simple-to-use cutting equipment for specialist users in the sign-making, wide format printing, and picture framing industries.

We design high precision manual cutting machines for specialist tasks, developing innovative ideas that speed up your workflow and increase productivity. Our primary focus is always on your safety. Keencut cutters are engineered to protect you whilst cutting the toughest materials.

We control quality and accuracy by manufacturing all major components at our Corby site in the UK. By using the highest quality raw materials and state-of-the-art machinery, we are confident of the reliability and durability of every Keencut machine.

Unlike other manufacturers, we state a specific accuracy level for every machine and offer a comprehensive 5-year guarantee.

With a continuous design and development programme, innovative use of premium quality materials, and the expertise of our engineers, we have set high standards that have never been equalled.

Our machines are an essential tool in many different industries and professions including print, textiles, packaging, flexographic printing, picture framing, museum curation, technical and design studios, education and graphic arts.

Flexo Plate Cutter

Evolution3™ Range

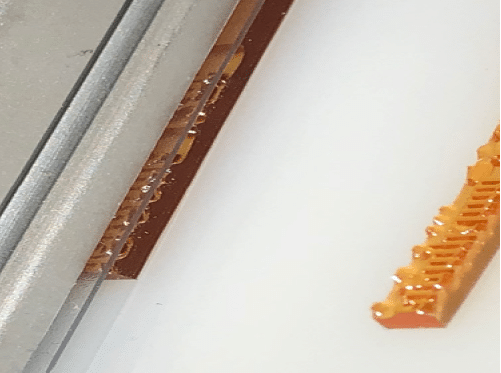

With the Flexo Plate Cutter, you can accurately pre-cut flexo on the flat. By using the sightline strip you can precisely align to your target marks for the first and second cut – there is no need to cut flexo on the round. There is less chance of costly mistakes, which often result in production downtime and the need to re-schedule work. You will quickly create seamless splices every time and save both time and money. The cutter is also intuitive to use and with a little training and practice, precise flexo cutting is achievable by all operators. The dual cutter head gives the option of creating a bevelled overlapping join, or alternatively a 5° undercut, so both plate edges meet perfectly when applied to the roller. The perfect join prevents ink traps or any deterioration of the adhesive. The Flexo Plate Cutter is specially designed to ensure your safety and increase production.

Features

Perfect accuracy for tight joins

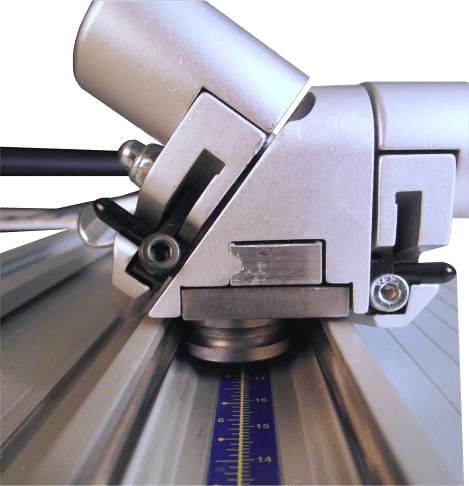

The design gives a lifetime of straight, precision accurate, silent cutting. The cutting head features a set of built-in self-aligning ball bearing rollers operating on twin steel tracks. There is zero play on the cutting head sliding action and the base is constructed of a heavy-duty, one-piece aluminium extrusion for complete stability. The precision accuracy produces seamless splices and eliminates costly mistakes, whilst the 5-degree undercut creates a tight join when the flexo is attached to the cylinder.Bevel & 5° undercut cutting head

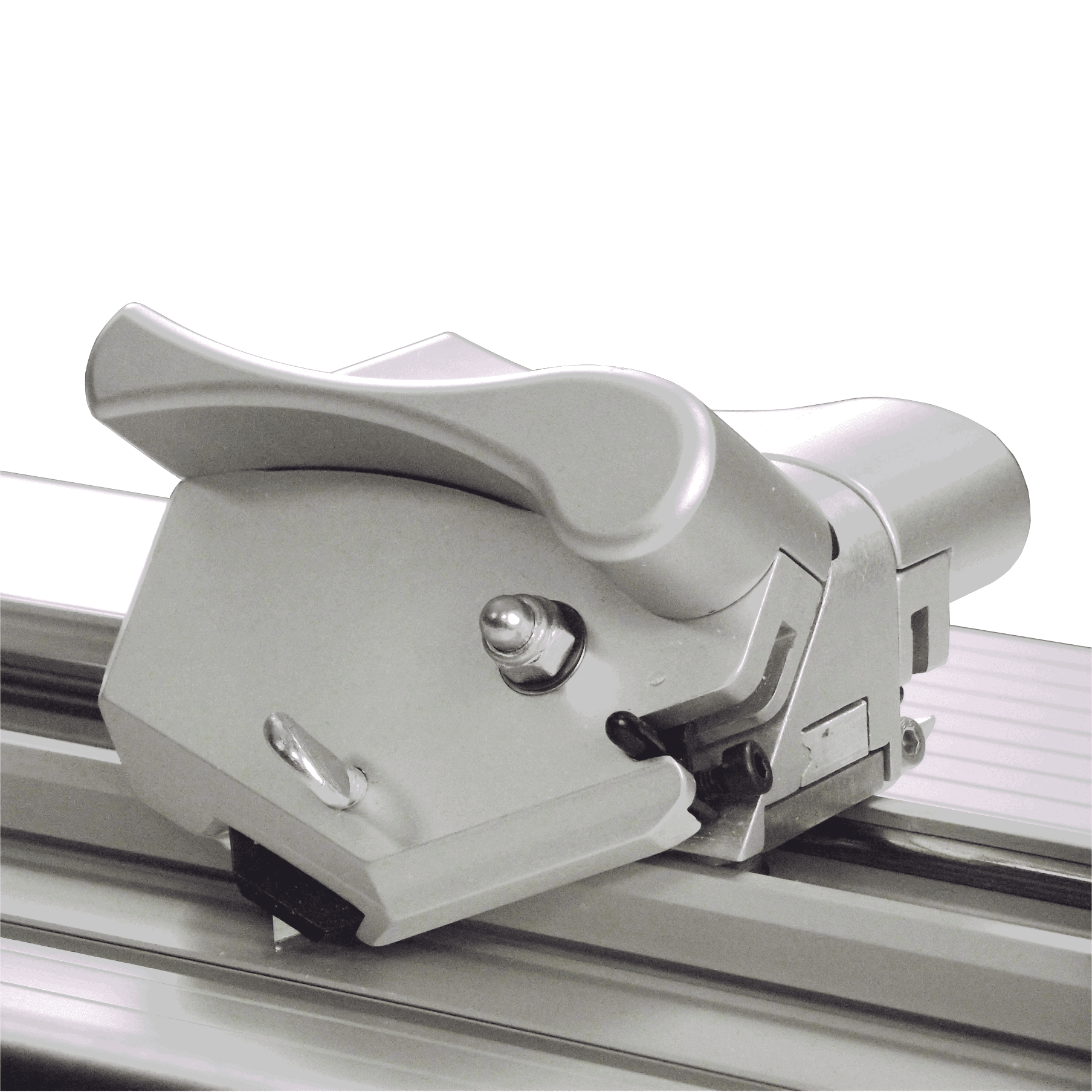

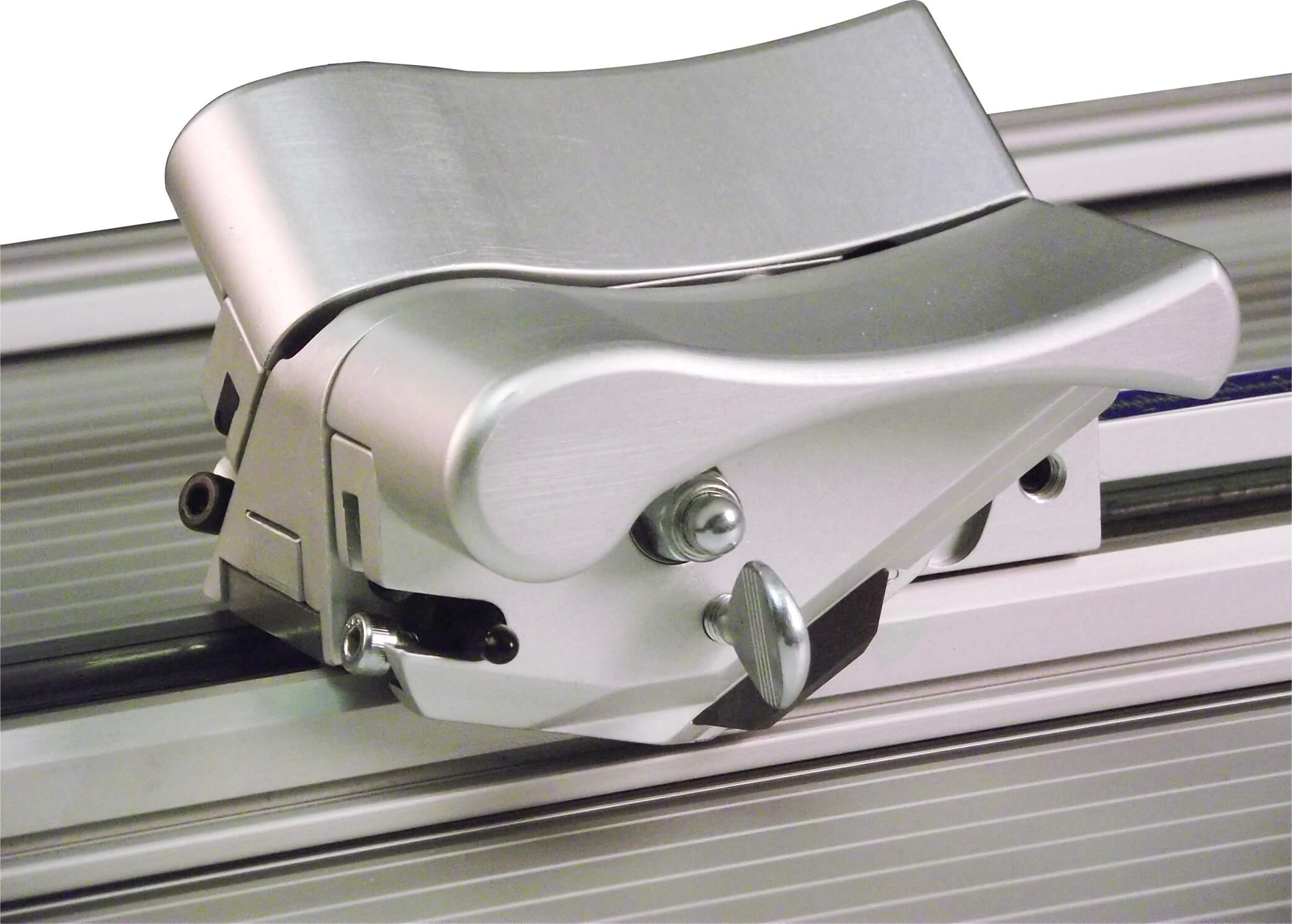

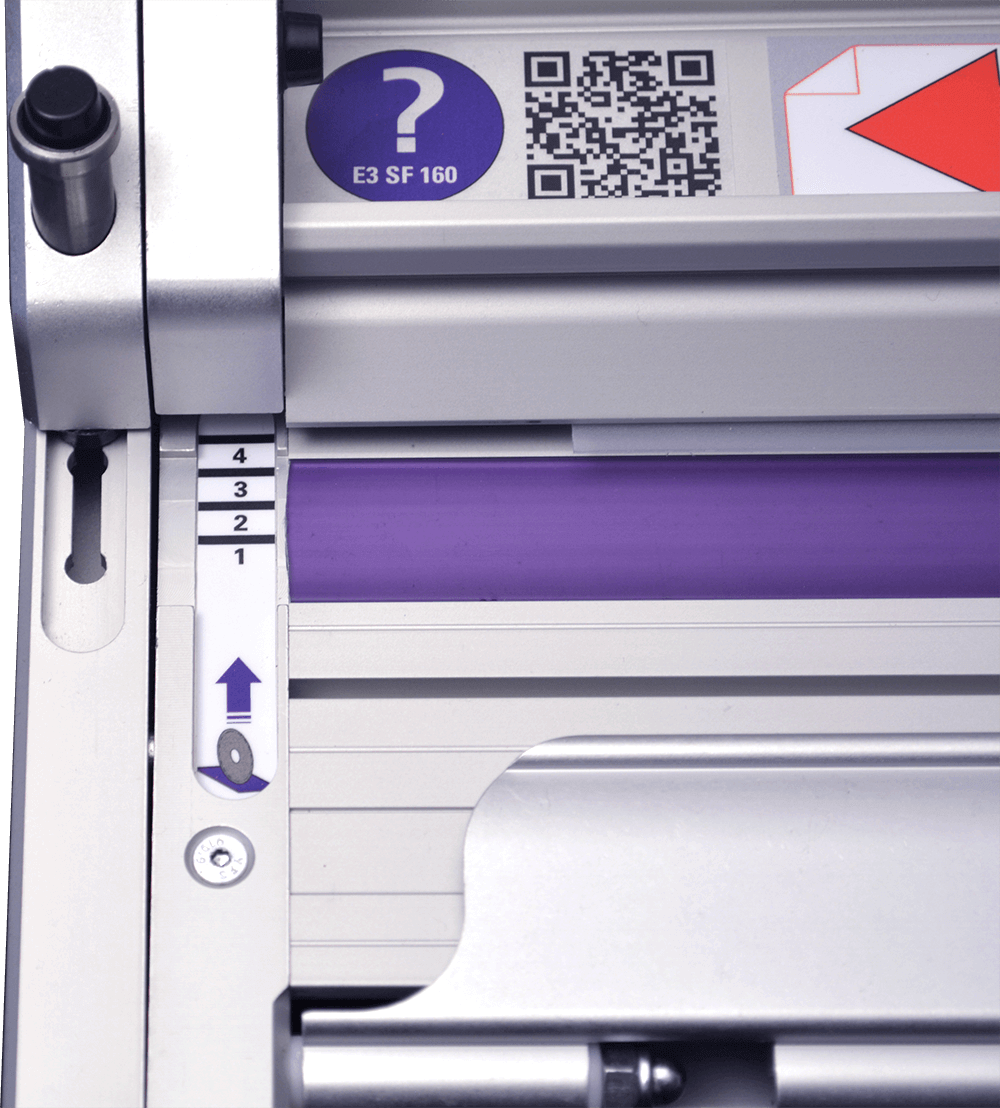

The spring-loaded bevel and 5° undercut blade holder features ball and thrust bearings for perfect alignment and superb blade control. The cutting head is mounted on two stainless steel tracks and hardened steel ball track rollers. All combined, they work together to give the ultimate in blade control.

Safety by design

The Flexo Plate Cutter ensures your safety and removes the dangerous practice of cutting flexo by hand with a knife. Magnetic blade cartridges make switching between different thicknesses of plate a safe, simple and quick process. Everything has been designed to ensure your safety.Simple operation

You can have various blade depths pre-set within different cartridges, so a precise and repeatable cut can be made by simply switching to a new cartridge. You can be confident of getting the right cut first time, every time and eliminating variability. The maximum blade depth for the bevel blade is 5mm (3/16″), the 5° undercut blade fitted with a trapezoidal blade is 10mm (3/8″) and a rectangular blade is 8mm (5/16″). Simple colour coding makes it easy to identify and calibrate the pre-set depths.

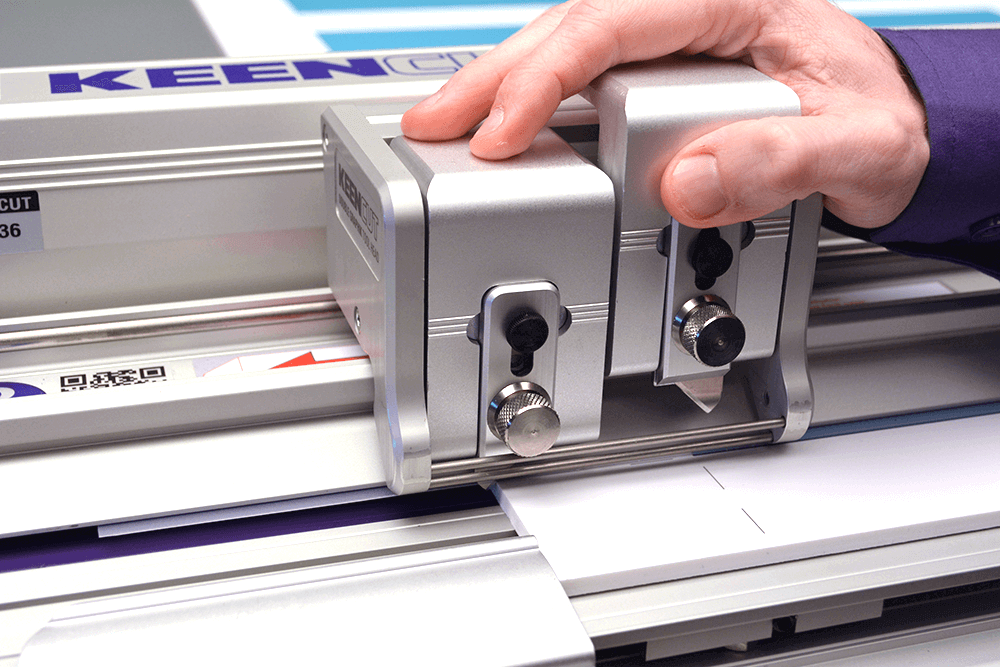

Ergonomically designed cutting head

The sculpted cutting head makes the Flexo Plate Cutter easy to use over long periods and is suitable for operation by left or right-handed users. A smooth sliding action provides precise cutting with no discernible friction.Five year guarantee

By manufacturing in-house, with only the highest quality materials, Keencut can guarantee that the Flexo Plate Cutter will provide reliable long-lasting and accurate service. All Keencut products are offered with a comprehensive five year guarantee.

In the box

15 Tech-S .015 blades

15 Tech-S .012 blades

15 Tech-D .012 blades

100 medium duty utility blades

Manuals, Useful Guides, Parts Diagrams: Support – Keencut

Keencut’s Evolution3 transforms manual cutting to set new quality and performance standards; it really does make accurate cutting easier than ever before.

Keencut’s Evolution3 transforms manual cutting to set new quality and performance standards; it really does make accurate cutting easier than ever before.

As market leaders, we always seek to advance cutting technology and the Evolution3 is truly a leap forward. The unique design offers technical developments not found on any other range of bench-top cutters.

There are three Evolution3 models: the SmartFold which can be stowed underneath the bench, the BenchTop which fixes to a work surface, and a portable FreeHand version.

Features

Lift-and-Hover technology

The Evolution3 SmartFold and BenchTop feature Keencut’s unique Lift-and-Hover (patent pending) technology, which enables single-handed, fast and accurate alignment of all media, irrespective of its thickness. A clutch device within the Lift-and-Hover system enables the clamping bar to be easily raised then lowered, so it hovers just millimetres above the material surface – there is no scooping or sag. The anti-sag mechanism means the cutter bar can be suspended exactly parallel to the media surface over the whole length of the cut with zero sag, even on the longest size of cutter.Future proof and versatile QuikSwap tool heads

The QuikSwap tool head family gives users the ultimate flexibility. Each tool is designed for a specific purpose, such as general cutting, creasing and fabric cutting and can be attached or detached from the cutter in seconds. You can mount single or multiple tool heads to suit your work and the Graphik tool head is supplied as standard, with other optional QuikSwap tools available to extend your cutting capability. New tool heads are also being developed to meet emerging requirements.

The versatile Rocker head

The optional Rocker tool head is the latest addition to the QuikSwap range. It is a versatile general-purpose tool for cutting materials such as banners, cardboard and foamboard up to 10mm (3/8″). The ergonomic design follows the natural curvature of your hand and offers maximum comfort for everyday cutting. It also provides two-way cutting – pulling to cut lighter weight materials and pushing for those that require more effort. For those who occasionally cut aluminium composite panels, such as Dibond or Alupanel, the Rocker head can be fitted with the Tech-D.012 blade. The cutting technique requires a series of careful strokes and we advise that you watch our video guide to perfect your cutting action.Guaranteed accuracy

The Evolution3 is the most accurate cutter of its type on the market and is guaranteed to cut within 0.2mm (0.008″) of a straight line for the full length of the cut. The in-built ultra-high precision accuracy, combined with the perfect alignment made possible using the sightline strip, means every butt-jointed panel will join seamlessly. This ultra-high precision accuracy will save you time and money with less waste and fewer mistakes.

Heavy duty reliability

The entire Evolution3 range has been built to last, using high quality materials and well tested engineering principles. The cutting head bearing system and clamping are tough enough to keep perfect blade control, even with the most difficult of materials. Keencut makes the majority of components on its precision CNC machines keeping tolerances and quality under constant control, this assures exceptional accuracy and total reliability.Five year guarantee

Like all Keencut machines, the Evolution3 is built to give many years of excellent service. All components are manufactured in-house to ensure quality and all Evolution3 cutters come with a five year comprehensive guarantee.

In the box

100 Graphik blades

Double Graphik tool head (mounted)