- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

Anilox Management from the Experts

Eaglewood Technologies Anilox Cleaning

Eaglewood Technologies was founded by the Mulheran family with the goal of constantly innovating our technologies. Pete, Mary, and Peter bring their nearly 100 years of experience in flexography to developing solutions for flexographers. Sani-Blast Inc. was purchased in 2007 which was the pioneer in anilox cleaning. In 2014, we introduced the revolutionary Sanilox™ Anilox Roll Cleaning System and 2015 Sanilox™ 2.0. 2017 has brought the advent of the game-changing Laserlox™ Systems, which evolved to the award-winning Sitexco Systems. In 2018, Eaglewood purchased Midstates Flexo Cleaning to better serve the upper Midwest cleaning market. A partnership with Alphasonics has been announced for 2020 to supply their advanced ultrasonic anilox cleaning equipment. Eaglewood Technologies now truly has an anilox cleaning solution for every flexographer!

Eaglewood Technologies was founded by the Mulheran family with the goal of constantly innovating our technologies. Pete, Mary, and Peter bring their nearly 100 years of experience in flexography to developing solutions for flexographers. Sani-Blast Inc. was purchased in 2007 which was the pioneer in anilox cleaning. In 2014, we introduced the revolutionary Sanilox™ Anilox Roll Cleaning System and 2015 Sanilox™ 2.0. 2017 has brought the advent of the game-changing Laserlox™ Systems, which evolved to the award-winning Sitexco Systems. In 2018, Eaglewood purchased Midstates Flexo Cleaning to better serve the upper Midwest cleaning market. A partnership with Alphasonics has been announced for 2020 to supply their advanced ultrasonic anilox cleaning equipment. Eaglewood Technologies now truly has an anilox cleaning solution for every flexographer!

Why Clean Anilox Rolls?

Anilox rolls are critical to efficient, quality printing so it is important to keep them clean

Eaglewood Technologies has helped printers and converters globally save money and improve their print quality by removing dried ink, adhesives, coatings, and varnishes from their rolls and sleeves. Our systems also easily clean coating rolls in offset presses and glue rolls on corrugators.

How will proper anilox roll cleaning benefit your operation?

The anilox is the heart of the flexographic printing press and any issues with the anilox roll will undermine the print quality. Here are some ways that a consistent clean across the entire anilox roll will benefit your operation:

- Avoid press downtime caused by having to scrub your anilox rolls with brushes

- Decrease the use of caustic chemicals — our products are eco-friendly

- Reduce the potential of rejected product from the customer

- Use less ink and less substrate

- Increase the lifespan of your anilox rolls

- The same system can clean anilox rolls, coating rolls, adhesive rolls, journaled rolls, and glue rolls

- The line count of your roll and the engraving will not affect how this system cleans

- Quickly deep clean your anilox rolls after power outages cause the ink to dry and plug the anilox

- The Sanilox™ System uses a food-grade media that is USDA and FDA approved for use in food-grade facilities

- Clean faster and more consistently than all other technologies, while being the economical and completely non-hazardous option

Eaglewood Technologies Sanilox™ Systems and Sani-Blast™ Mobile Service have the longest track record of cleaning rolls in the industry – over 20 years and tens of thousands of rolls! We also have the Laserlox™ Anilox Cleaning Systems for packaging and label printers.

Eaglewood Technologies is the proven, reliable option to clean your rolls and can do so on-press or off-press in a fraction of the time and cost of other systems.

Sanilox™ Cleaning Systems

Sitexco Cleaning Systems

XPress™ Anilox Cleaning Service

The Fastest and Most Efficient In-Press Anilox Roll Cleaning System on the Market

The Sanilox™ system is an innovative, environmentally-safe anilox roll cleaning system engineered by Eaglewood Technologies. Sanilox™ is easy to operate and is controlled by a simple touch screen interface.

Sanilox™ Advantages:

- Quick and easy to use

- No Line Screen or Geometry Limitations

- One system cleans anilox rolls of any diameter

- A color touch screen makes it easy to operate and track roll inventory data

- Increases the life of your anilox rolls

- One year warranty and 90-day money-back guarantee

Sanilox™ Cleans:

- Any adhesive, ink, coating, varnish or glue chemistry

- Journaled rolls

- Sleeves

- Gravure rolls

- Glue rolls

- Coating rolls

- Adhesive rolls

How It Works

The Sanilox™ media delivery system fractures the media to below six microns when applied at 35 psi – this means the media reaches the bottom of the cell, ensuring the entire cell gets cleaned (not just the walls of the cell). Other media blasters, including plastic, use a lower pressure in order to “recycle” and re-use media. At a lower pressure, the cleaning time can take up to four times as long. “Recycling” units are less effective cleaning machines since the ink and anything else that is being removed gets recycled as well. This means the roller never truly gets cleaned and dried ink is driven into it over and over.

The Sanilox™ media delivery system fractures the media to below six microns when applied at 35 psi – this means the media reaches the bottom of the cell, ensuring the entire cell gets cleaned (not just the walls of the cell). Other media blasters, including plastic, use a lower pressure in order to “recycle” and re-use media. At a lower pressure, the cleaning time can take up to four times as long. “Recycling” units are less effective cleaning machines since the ink and anything else that is being removed gets recycled as well. This means the roller never truly gets cleaned and dried ink is driven into it over and over.

The Sanilox™ System uses a special formulation of sodium bicarbonate specifically designed for the deep cleaning of aniloxes. This media is manufactured by Armex® the industrial division of Arm and Hammer. The Anilox formulation is USDA and FDA approved for use in food-grade packaging facilities. This media breaks down enough to reach the bottom of the cells of even the finest line screen aniloxes on the market.

Flexible Applications

Sanilox™ In-Press:

- Cleans anilox rolls in-press by attaching the track via magnets to the print deck.

Sanilox™ Off-Press:

- Cleans anilox rolls off-press by using the Anilox Roll Cart attachment. The operator can start the system, walk away, and return to a clean roll.

System Specifications

Sanilox™ System:

- Footprint: 63” L x 27” W x 65” H

- Weight: 985 lbs

- Air: 80 psi, 3/8” quick connect fitting

- (2) 110 volt / 20 Amp dedicated electrical outlets

Anilox Roll Cart

- Footprint: 107” L x 32” W x 41” H

- Weight: 560 lbs

- (1) 110 volt electrical outlet

DEEP CLEANING

The Sanilox™ system fractures the media to below six microns when applied at 35 psi. This means the media reaches the bottom of the cell, ensuring the entire cell gets cleaned (not just the wall of the cell).DUST-FREE OPERATION

The Sanilox™ system uses a two-stage HEPA filtering system that delivers dust-free operation throughout the entire cleaning process. There is one collection point for easy disposal and zero mess.AUTOMATION

The touch screen interface allows for information to be easily entered and stored for simple recall.IN-PRESS AND OFF-PRESS OPTIONS

The Sanliox™ system can be quickly and easily transformed from an in-press to an off-press system. No other machine on the market today offers this flexibility.

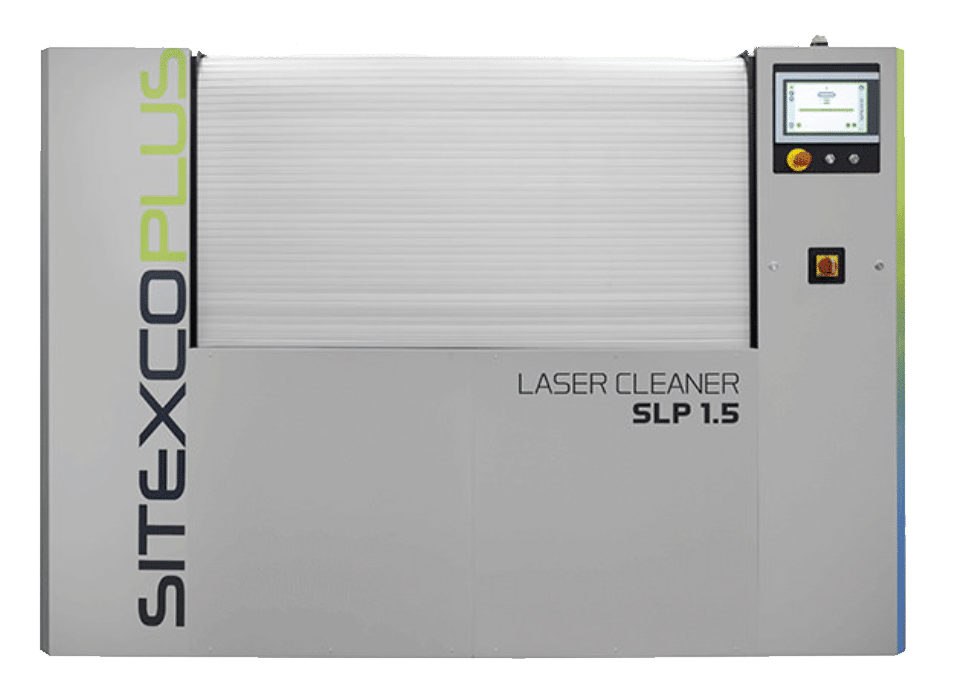

The Most Advanced Roll Cleaning System in the World

The best just got better. Looking for the fastest, safest and most effective way to deep clean your aniloxes? The Sitexco+ Laser Anilox Cleaning System, based on the award winning Sitexco System, is here. The Sitexco+ system is the fastest cleaning system in the world. Easily clean any type of ink, coating, varnish, or adhesive chemistry. Our patented cleaning method ensures a perfect clean that is safe on your aniloxes, even after the 200th cleaning cycle.

Fastest and Most Effective Cleaning:

- Proven Technology – 11+ Years of Innovation

- Longest Lasting Laser

- Fastest and Safest Laser Cleaning System

- Safe for Operators and Your Facility

- Safe for Aniloxes

- Cleans Any Type of Ink: Water-Based, Energy Curable (UV/LED), Solvent-Based, Adhesives, Varnishes, and Coatings

- Easily Clean: Anolox Rolls, Sleeves, Gravure Cylinders, Glue Rolls, and Offset Coating Rolls

Intelligent and Easy to Operate

- Simple Touch Screen Interface

- No Line Screen or Geometry Limitations

- No Bearing or Gear Removal

- Does Not Generate Any Waste

- Does Not Require an Air or Water Source

- Best Warranty

How It Works

The Sitexco+ system achieves success by using the highest quality components, proprietary optics, and software. The precise cell-by-cell cleaning method allows each individual cell to be cleaned rather than a large area. As a result, the laser energy is not unnecessarily affecting the engraving (which causes premature wear and inconsistent cleaning results). Precision is the key in proper cleaning results, speed, anilox longevity, and performance.

DEEP CLEANING

Sitexco+ lasers ablate any ink chemistry with great ease. Whether it's ceramic or chrome, there is not a more effective cleaning method available.SUSTAINABILITY

The only truly sustainable cylinder cleaning technology on the market. Requires no air or water source and has exceptionally low energy consumption (using only 1.5-1.9 kw of power per hour).FULLY AUTOMATED

The touch screen interface allows for information to be entered, stored, and easily recalled. Simply place an anilox into the machine, select which cylinder is being cleaned, and turn the machine on.SAFETY

Safety guards assure that the machine is shut down immediately if the safety guards are bypassed or if anyone tries to gain access to the machine while it is on."TELEGRAM" SMARTPHONE FEATURE

The operator can seamlessly communicate with the Sitexco+ machine via the telegram feature on a smartphone. Notifications such as end-of-cycle alarm, status updates, and errors can be sent directly to the operator, which allows other work to be done while aniloxes are being cleaned.CLOUD-BASED FEATURES

Setup, manage, and access roll reports from anywhere at anytime. Schedule reports to be emailed directly to you on a daily, weekly, or monthly basis. Information is always at your fingertips!FASTEST SYSTEM AVAILABLE

The Sitexco+ system is the fastest laser system on the market. Because of our patented cell-by-cell cleaning capabilities, time is not wasted on cleaning already clean cells. Contact us for a LIVE demonstration today!Now In 3 Available Laser Options

The Sitexco+ machines now come with three laser options to fit your unique cleaning needs. All three lasers provide the same exact cleaning results and capabilities. These options will simply help match your throughput or cleaning frequency demands to meet your budget requirements.

With these three laser options, laser anilox cleaning has become more attainable throughout all market segments of Flexo, Gravure, and Offset printing disciplines.

Fast and Exceptional Anilox Cleaning Services

Eaglewood Technologies has been providing anilox roll cleaning services for more than 25 years. Our team of skilled technicians has successfully cleaned nearly 30,000 rolls on-site at our customers’ facilities and off-site at Eaglewood Technologies. Our service is fast, effective, and safe. XPress Service brings our proven Sanilox™ roll cleaning technology to you. Expert technicians will perform service on-site at your facility or off-site at Eaglewood Technologies.

We Clean:

- On-site at your facility or off-site at Eaglewood Technologies

- Any ink, coating, varnish or glue chemistry

- Anilox sleeves

- Rolls with journals

- Glue rolls on corrugators

- Offset coating rolls

- Gravure cylinders

PROVEN RESULTS

Our skilled technicians provide roll reports that illustrate the effectiveness of the cleaning service and the condition of your anilox. Deep cleaning will save you money, increase productivity, and extend the life of your rolls.MAXIMUM SAFETY

Our services are safe for your rolls, your people, and the environment.OUR TECHNOLOGY

XPress™ Anilox Cleaning Service uses our proven Sanilox™ technology on-site at your facility. Our off-site cleaning technologies include either Sanilox™ or our award-winning Sitexco Laser System.How We Clean

Sanilox System

The Sanilox™ media delivery system fractures the media to below six microns when applied at 35 psi. As a result, the media reaches the bottom of the cell which ensures that the entire cell gets cleaned (not just the cell walls). The Sanilox™ system is safe for your cylinders, your people, and the environment.- Sanilox™ In-press cleans anilox rolls in-press by attaching the track via magnets to the print deck.

- Sanilox™ Off-press cleans anilox rolls by using an Anilox Roll Cart attachment.