- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

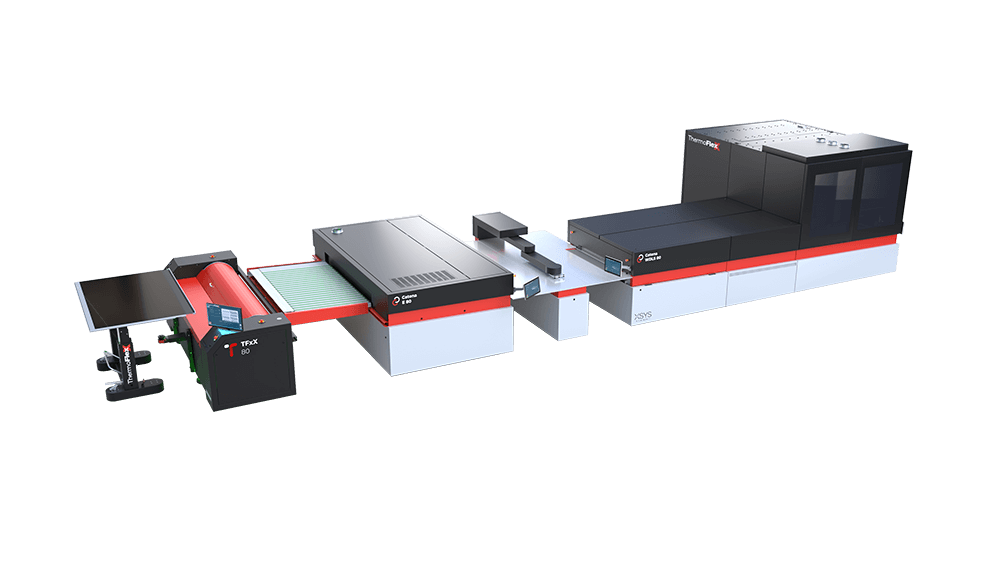

ThermoFlexX Catena+ Plate Processing Equipment

The ThermoFlexX Catena+ line by XSYS is a fully automated line with minimum operator intervention, resulting in more plate production, long after the end of a shift.

It features an open system allowing for easy plate loading and full access to production data of all modules to provide the user with a new level of proactive maintenance.

Catena Products

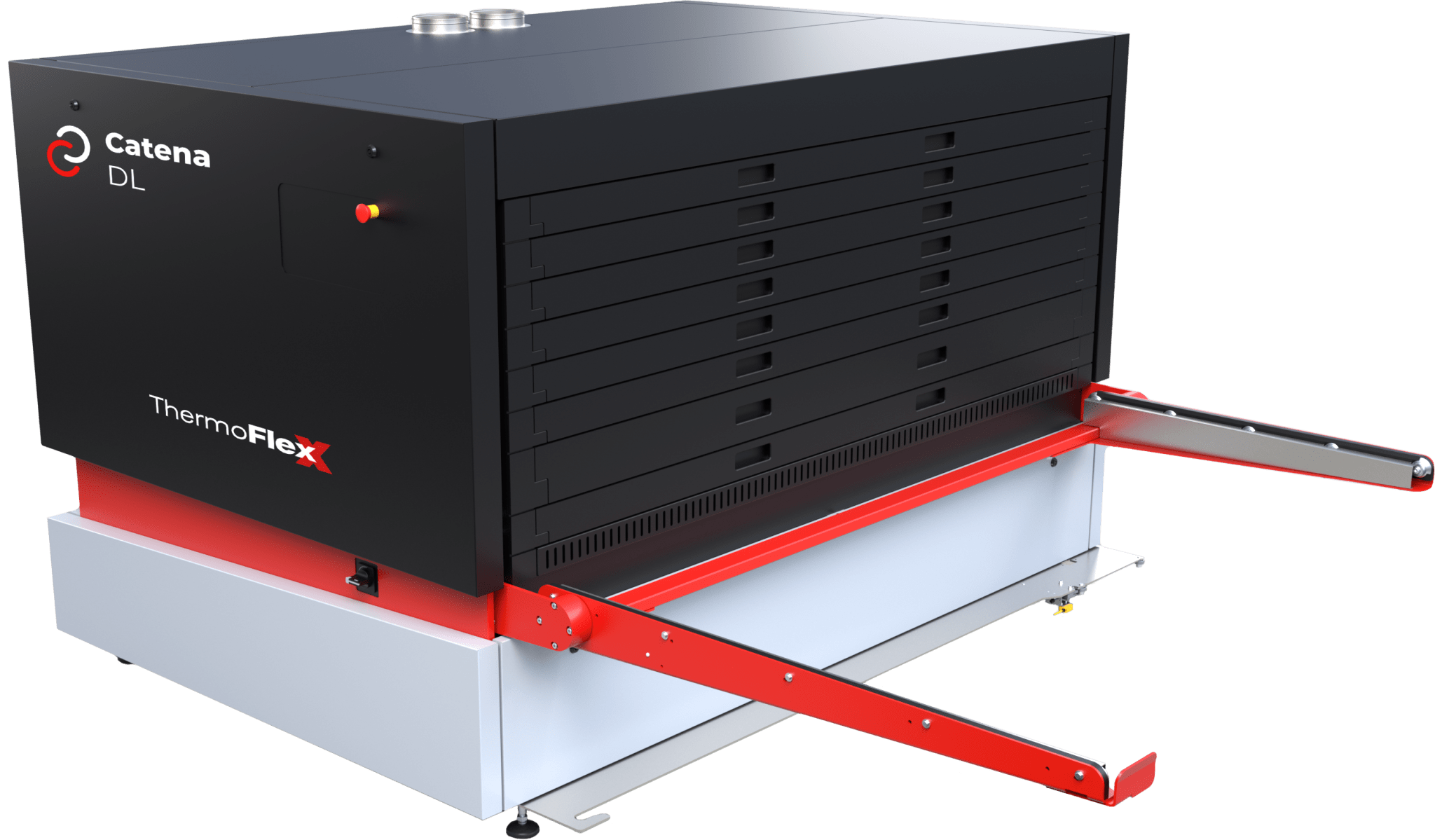

Catena-DL

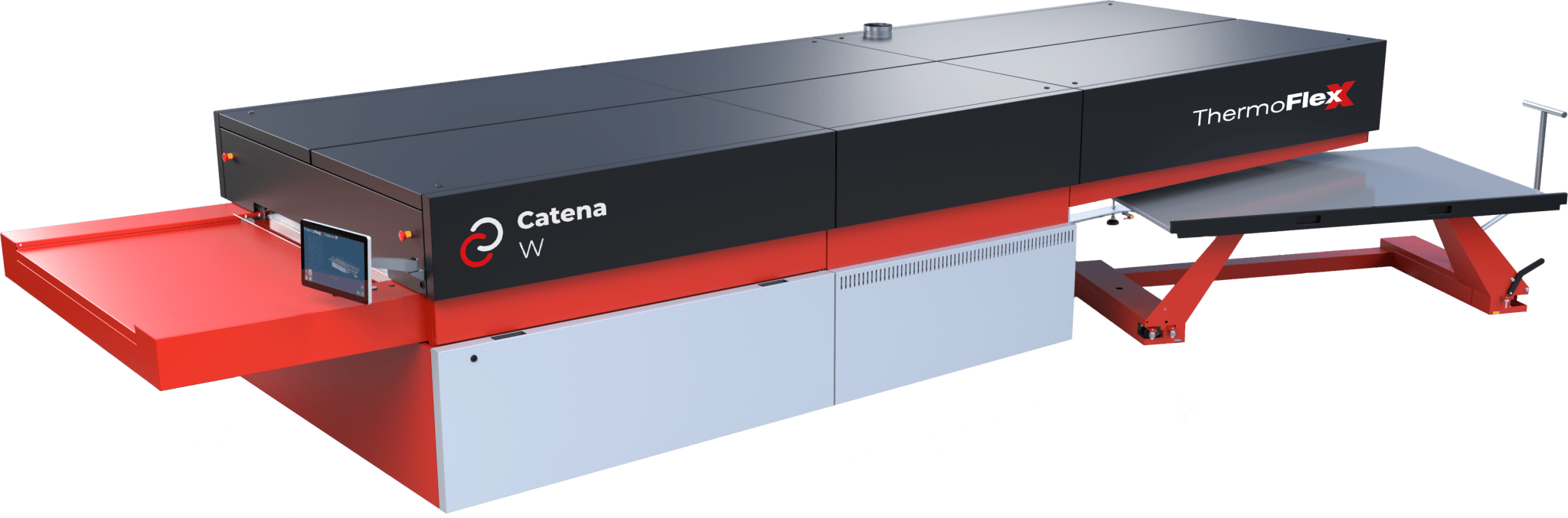

Catena-W

FV size dryer & light-finisher unit for flexo plates

Features

- Dimensions: Width 2520mm, 3003mm inc. monitor (99/118”) Depth 1687mm, 3150mm inc. lift arms (66/124”) Height 1623mm, 1888mm lift arms up (64/74”)

- Plate Thickness: Max 7mm / 0.276”

- Plate Size: Max 1320x2032mm / 52×80”

- Electrical 380V 3ø N+PE 50 / 60Hz 20A

- Weight: 1800kg / 3960lbs

- Packed Dimensions: 2118x2770x2060mm / 83x109x81”

- Extraction: 2x160mm

Individually Controlled Dryer Sections Independent

Independent heaters, sensor control and ventilation for all 6 dryer sections. This ensures exact temperature and timings for all plates. Only required stations need to be active for economic operation if only a few sections are required.

Precision Light Finishing

UVA and UVC lamps are monitored and controlled to ensure ultimate consistency from plate to plate. Sensors test intensity before each plate and tubes are monitored to ensure timely replacement when necessary. A record of lamp performance can be available for every plate for ultimate QC tracking.

ThermoFlexX Monitoring

All critical information such as motor current, controllers, operating conditions and working temperatures are monitored. This information can be stored and made available for total plate QC records. ThermoFlexX ProServeX provides a cloud-based, constant monitoring service of all key components throughout the range. A brand-new level of predictive maintenance with on-line support is available. The need for physical service-interventions is minimised.

ThermoFlexX Graphical User Interface

New levels of information and plate production progress are displayed on stylish monitors on each Catena unit. ThermoFlexX smart communications integrates imager, LED exposure, washer and dryer.

Operator Safety and Convenience

A unique plate lift and a carrier tray for each section makes it easy for a single operator to handle the largest plates. All drawers can easily be used with no strain. With a Catena-W wash-out unit, the shuttle ensures easy transport of plates for loading into the dryer section via the lift. This avoids both the risk of damage or the operator having to handle solvent wet plates.

Wash-out unit for flexo plates

Features

- Dimensions: 6851 x 2060 x 1348 mm / 270 x 81 x 53”

- Plate Thickness: Max 7 mm / 0.276”

- Electrical: 380V 3ø N+PE 50 / 60Hz 20A

- Packed Dimensions: 3 Main cases

- Plate Size: Max 1320 x 2032 mm / 52 x 80”

- Extraction: 600m³/h 1 x 160mm outlet

- Weight: 3250 Kg / 7150 Lbs

- Compressed Air: 6 Bar Min 30L / min peak 250L / min (10 sec)

Highest Productivity with plate Alignment

Unique plate alignment when loading the plate into the Catena-W avoids plate skew during transport. The advanced plate queuing, limiting the distance between plates to 50 cm, maximizes throughput for the highest possible productivity. At the end of the wash-out process a shutter door operates as a buffer before dropping the plate onto the shuttle.

Plate Shuttle

Large heavy plates can be handled easily by a single operator, eliminating any human touchpoint. Furthermore, the shuttle also provides a safe second rest spot for plates in production allowing a minimum gap between plates in the queue. The result is, more plates per shift, due to increased throughput.

ThermoFlexX Graphical User Interface

All ThermoFlexX equipment utilises leading brand PC’s, monitors and the latest Windows OS aimed specifically at high-end system development. ThermoFlexX Graphic User Interface is displayed via a 24” Full HD touch-screen making operation extremely fast and simple. Key information is clearly presented to theoperator for ease-of-operation without errors.

ThermoFlexX Monitoring

All critical information such as motor current, controllers, operating conditions and working temperatures are monitored. This information can be stored and made available for total plate QC records. ThermoFlexX ProServeX provides a cloud-based, constant monitoring service of all key components throughout the range. A brand-new level of predictive maintenance with on-line support is available. The need for physical service-interventions is minimised.

Closed Operation

A sealed environment with efficient extraction ensures minimum solvent fumes in the working area, even when opening the doors a minimum of solvent smell will be perceived as the solvent section is completely enclosed.

Automatic Pinbar

Plate punching is not required. A cleverly designed pinbar system transports the plate flawlessly through the washing process and returns for the next plate, no need for manual transportation of the pinbars. Three pinbars ensure continuous availability. Only an edge of 8 mm plate material is required to pull the plate through the wash-out unit (other systems typically 20 mm).