Description

A smarter design for greater productivity with less maintenance, less downtime, and lower operating costs

nyloflex® Xpress Thermal Processing System for flexographic printing plates – incorporating the speed of thermal plate making with incredible plate and print quality.

At the heart of the processing system lies the nyloflex® Thermal Printing Plates specifically formulated to perform exceptionally well in the nyloflex® Xpress Thermal Processor.

Key Benefits

Reduced Operating Costs

- With its short wave IR preheating system that is specially designed for its heating depth precision, you can expect to see a decrease of up to 88% in your electricity usage

- Features zoned lamps for maximum energy efficiency at any plate width

Excellent Quality & Improved Productivity

- Features high-quality thermal plates, a thermal flat-top dot, and round dot plates that are optimized to the infrared preheating system

- The plates are thoughtfully designed to resist non-woven impressions and display high cleanout between dots for consistent solids printing time and time again

- Great for markets in tag & ideal, flexible packaging, and paper & board

Sustainability and Health & Safety

- Near elimination of VOCs, the nyloflex® Xpress Thermal Processing System delivers efficient energy usage and uses as much as 30% less fabric in its developer rolls

- Weighing less than 30 lbs, users can benefit from working in a safer environment due to the lightweight, more sustainable developer rolls

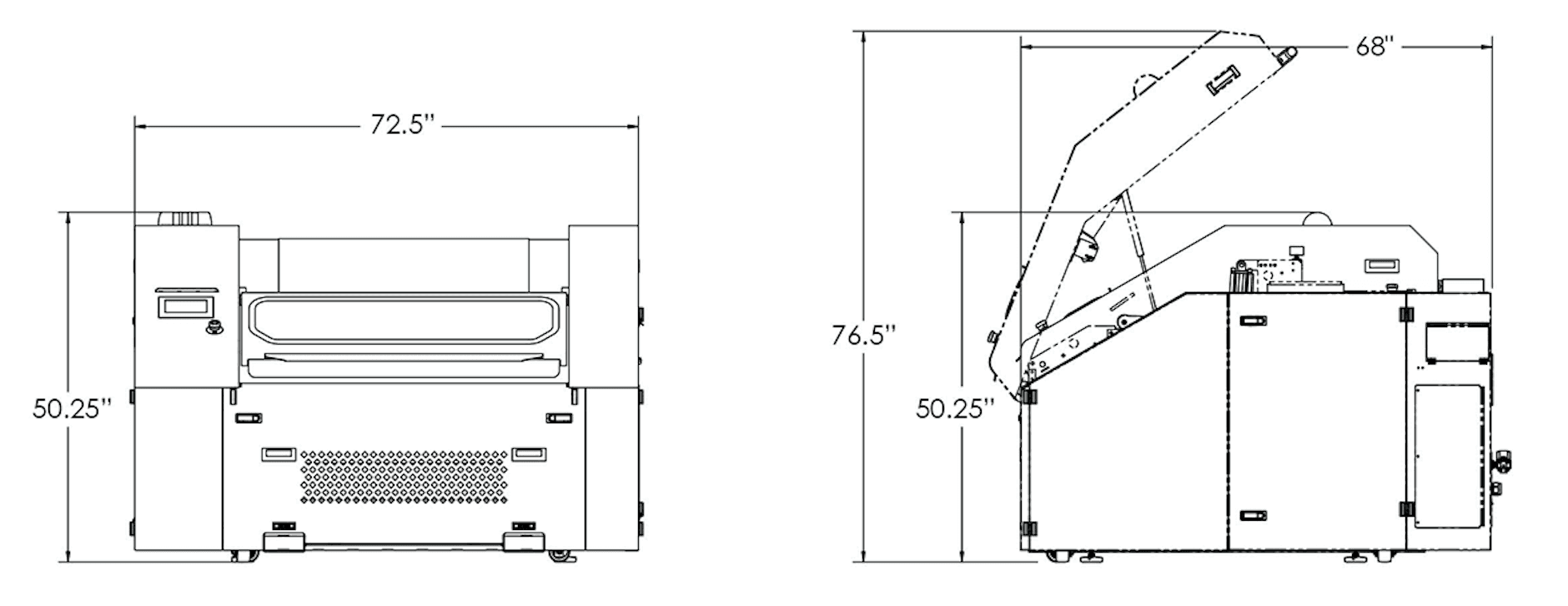

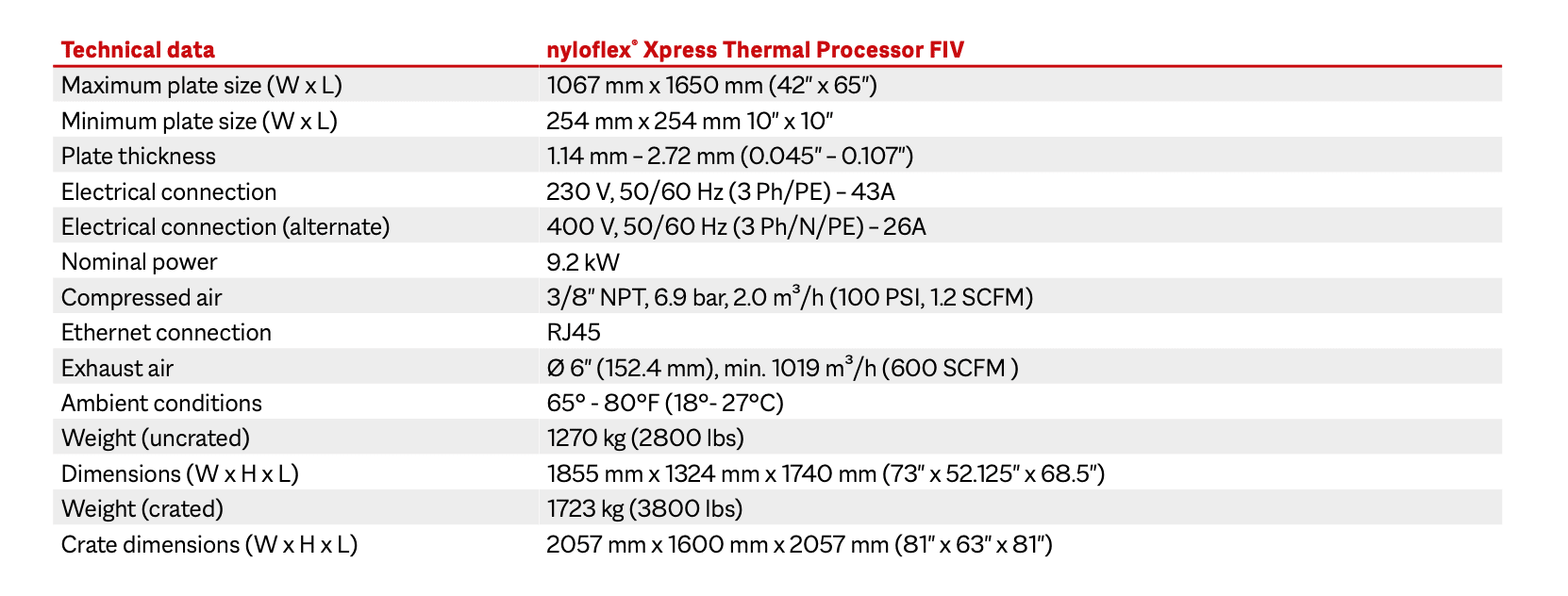

Equipment Dimensions

Technical Data

nyloflex® Xpress Waste Recovery Program

A complete solution for removal of waste materials

- All consumable items from the process collected:

- Used developer rolls

- Raw or finished plates (with or without stickyback)

- Cover sheets and foam separators

- Empty plate and developer roll boxes

- Palletize the boxes and attach provided shipping label

- Simply call or email to arrange pick-up

- Waste will be routed for recycling or to waste-to-energy facility where available

Learn More

![]() Download the Xpress Thermal Processing System Brochure

Download the Xpress Thermal Processing System Brochure

![]() Download the Xpress Thermal Processor Brochure

Download the Xpress Thermal Processor Brochure