Best Practices to Maximize the Potential of Your Pre-Press Arsenal

In the flexographic industry, technology is always advancing and traditional equipment is constantly being replaced with newer and more efficient alternatives. Pre-press equipment is no exception to this. Because pre-press operations are one of the most important tasks in flexographic printing, it is important to have the most up-to-date equipment available so you can improve workflow operations and productivity.

To run a successful flexo business, it is critical to regularly maintain and manage each piece of pre-press equipment so that you can maximize its potential. Proper maintenance and management also allow operators to make sure that everything is running smoothly and as efficiently as possible. Below are some of the best pre-press practices to streamline production and operations to save time and money.

1. Proper Classification

Proper planning and cataloging are important for any business, and it isn’t any different when it comes to your pre-press room. Operators need to classify their pre-press arsenal according to its type and working characteristics to develop thorough maintenance plans.

In general, there are 7 main categories where we can group pre-press equipment based on its function, and they are as follows:

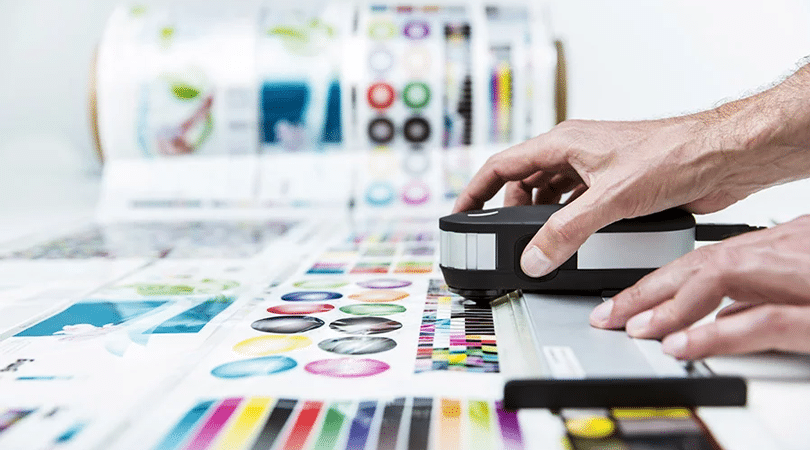

- Color Management Equipment: Equipment geared towards ensuring a consistent color palette across multiple devices and projects via digital color management software.

- Direct Plate-Making Equipment: Plate-setters and the software required to run plates. In general terms, it covers CTP equipment and anything involved in finalizing a plate.

- Output Equipment: Equipment that plays a role in the final shape or presentation of a printed piece.

- Printing Equipment: The tools and machinery used to create a product. In general terms the printing machine and plate machine.

- Proofing Equipment: Equipment geared towards the printing of proofs for your clients.

- Prototyping Equipment: Equipment that allows your press to present mock-ups or prototypes to clients before starting full production. They can be digital or physical.

- Quality Control Equipment: Software and tools designed to confirm the quality of a piece before production starts.

Once all pre-press equipment is properly classified and categorized, operators can begin to assemble and evaluate maintenance plans according to each piece of equipment’s usage, general lifespan, potential wear, and cleanliness. This way, operators will understand just how much each piece is used and how often they should maintain it.

2. Maintenance Practices

Every flexographic business should develop specific maintenance and implementation plans to stay on top of all their pre-press arsenal. It is one of the most important measures operators should take regularly. Developing regular maintenance schedules and plans will ensure each piece of equipment remains in its best shape. Because equipment must be cleaned and maintained efficiently, operators must create a fixed schedule of which equipment needs to be cleaned each day and based on its usage and wear.

Not only that but each department must keep a clear log of who is checking each piece of equipment on any given day. Report logs allow everyone on the team to keep track of how each piece of machinery is functioning and whether there is any abnormal activity or damage to it. If unusual behavior is observed, a maintenance plan should be properly enacted. Operators who keep everything in an organized state will be able to accurately pinpoint and solve problems that arise. Ultimately, maintenance comes down to consistency and proper planning – something each team should constantly be invested in.

3. Cleaning Solutions

Acquiring the proper cleaning solutions is essential in ensuring that your pre-press equipment is kept in its best shape. No matter what type of equipment you are using, particles and residues can slip into crevices and empty spaces. When these are not properly cleaned, the overall quality of your product can be affected. Efficiency and quality are the two most important factors when it comes to flexographic businesses. To make sure you are putting out high-quality work as efficiently as possible, it is essential to regularly clean your pre-press equipment with quality cleaning solutions.

If you’re not sure which cleaning solution works best for your equipment, it is a good idea to partner with a flexo manufacturer that provides an extensive selection of cleaning products. Your partner will be able to provide you with all the cleaning solutions you need from one single source so you don’t have to worry about ordering from multiple suppliers. Not only that but the right partner will be able to offer you insight into which cleaning solutions work best with the equipment you currently have. Working with a knowledgeable partner will lower your overall costs and minimize the risk of equipment damage.

4. Environmental Control

For optimal performance of each pre-press equipment, it is important to evaluate the environment and working conditions of your workspace. Most pre-press equipment is electronic. This means each piece of equipment has integrated circuits and other delicate electrical components that can be affected by the temperature and humidity of its environment.

Extreme changes in temperature or humidity can affect the sensitivity of these components and cause delays in printing and alter the lifespan and quality of the whole machine. To avoid this, operators must ensure that each workspace is custom-tailored to the needs of their equipment. Setting your workspace at its optimal temperature will allow for your pre-press machinery to function in its best condition. The most reliable way to do this is to install air conditioners. This allows your team to constantly control the temperature and humidity of your workspace.

One more thing to keep in mind is that dust is a major concern when it comes to the well-being of your pre-press equipment. Even minuscule amounts of dust can affect the entire output process and clog ink ejectors or moving parts. This can potentially decrease the overall quality of the end-products. This is why it is crucial to regularly clean and maintain both the workspace and the equipment in it.

5. Employee Training

As mentioned earlier, there are countless new and innovative pre-press equipment making their way into the flexographic industry. Businesses that can seamlessly adopt these types of technologies, in addition to the traditional equipment they already have, will be able to stay relevant and competitive in today’s flexographic landscape. When it comes to adopting new equipment, it is important to note that they come with new processes and operations that will require further training for efficient operation. This means that employees must stay vigilant and well-informed on each piece of new equipment that comes into play.

Training as a whole is one of the most important practices for any company that wants to remain competitive and ensure maximum productivity. Acquiring new equipment won’t make a difference unless the staff handling it has been properly trained for its operations. A lot of the time, adopting new software and machinery can pose a challenge for businesses due to a lack of understanding and knowledge. This leads to workflow inefficiencies and low-quality end-products. Think about partnering with a flexo manufacturer and distributor that can ease the transition of adopting new equipment. The right partner in flexo innovation will fully install and implement new equipment and provide training and education to your staff.

Training as a whole is one of the most important practices for any company that wants to remain competitive and ensure maximum productivity. Acquiring new equipment won’t make a difference unless the staff handling it has been properly trained for its operations. A lot of the time, adopting new software and machinery can pose a challenge for businesses due to a lack of understanding and knowledge. This leads to workflow inefficiencies and low-quality end-products. Think about partnering with a flexo manufacturer and distributor that can ease the transition of adopting new equipment. The right partner in flexo innovation will fully install and implement new equipment and provide training and education to your staff.

Key Takeaways

The world of flexo printing is ever-evolving. Businesses who want to stay above the fray should not only obtain the most up-to-date technologies but also know how to maximize their potential. Because new and advanced equipment is an investment, operators must do what they can to make sure they are getting the most out of each piece of equipment. Partnering with a qualified and dedicated flexo manufacturer is the best way to receive the proper equipment and training you need to boost your workflow operations.

Anderson & Vreeland provides flexographic printers with creative solutions that are custom-tailored to every unique client and business model. The A&V team provides operators with the knowledge and best practices for all operations to run as smoothly and efficiently as possible.

Start Maximizing Your Potential Today