The Evolution of Resolution: How Advancements in Flexo Digital Equipment Have Changed Print Quality

Founded in 1905, Excelsior Marking is a pre-press printing service firm located in Akron, Ohio. For the last 50 years, Excelsior has made a name for itself thanks to its high-quality flexographic printing plates. As one of the only prepress houses that is ISO 9001:2015 certified with quality systems, Excelsior continues to provide top-quality products and services to its clientele.

Founded in 1905, Excelsior Marking is a pre-press printing service firm located in Akron, Ohio. For the last 50 years, Excelsior has made a name for itself thanks to its high-quality flexographic printing plates. As one of the only prepress houses that is ISO 9001:2015 certified with quality systems, Excelsior continues to provide top-quality products and services to its clientele.

The Road to Better Resolution Quality

Currently, the global flexographic printing market is growing at a consistent pace, with a projected value of over $20 billion by 2025. At the forefront of this growth is the wide web press market as its versatility provides important applications in the world of consumer good packaging and labeling.

“We knew about the growth opportunity within the industry and made it our focus to enhance our capacity, speed, quality, and resolution,” said Dave Sutter, owner of Excelsior. Combining its new focus and its extensive experience in the wide web market, Excelsior knew it needed to improve its printing capabilities on the digital side to offer better services for operators and capture more market share. The team needed the right technologies to cover a wide variety of clients and industries. To fill these requirements, Excelsior partnered with Anderson & Vreeland to stay on top of all the current market and technology trends to enhance productivity and efficiency.

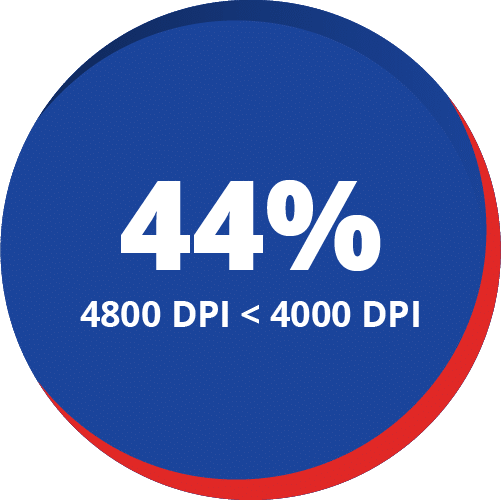

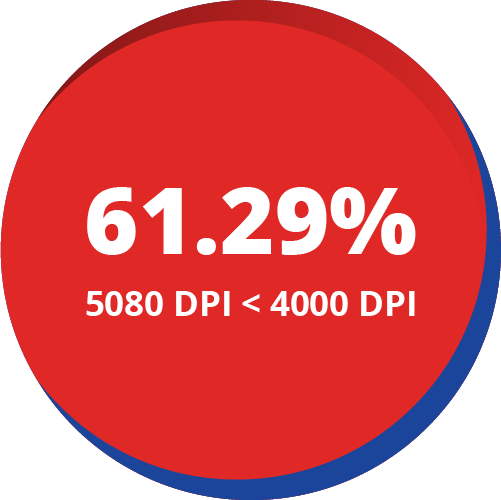

Hitting the ground running, Anderson & Vreeland identified several advancement opportunities Excelsior could implement into its current workflow to improve resolution quality. These improvements included installing the XSYS digital imager, which produces plates at resolutions of up to 5080 dpi, and the SCREEN digital imager that produces plates at resolutions of up to 4800 dpi. With the new equipment installed into its workflow, Excelsior is able to offer higher quality resolutions unlike before as both XSYS and SCREEN improved print quality by 66% and 44% respectively over competitive offerings. Both the XSYS and SCREEN digital imagers consist of leading-edge hardware and workflow software based upon proven technology and digital workflow solutions. These new additions to Excelsior’s workflow operations enable Excelsior to consistently produce high-quality flexographic plates at high levels of output with the newest industry standards.

Other operational optimizations Anderson & Vreeland found included upgrading the company’s software that it was using to prepare files and enhance its proofing system.

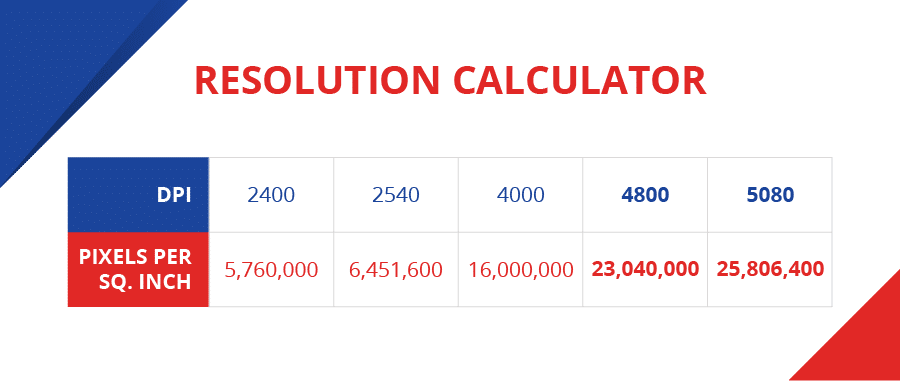

The Truth Is in the Math

One thing to remember is that print quality is not a subjective matter. “This is a mathematical truth – it’s all in the numbers. The numeric value on the imager says it all.”

As seen in the table above, an imager with a resolution of 4800 dpi images at an output of 23,040,000 dpi pixels per dot per inch and a resolution of 5080 dpi images at an output of 25,806,000 dpi pixels per dot per inch. Compared to 4000 dpi, there’s up to over 60% more detail per surface area. This goes to show that the math of it all cannot be disputed. There is a significant difference between the resolutions of imagers that are 4000 dpi compared to 5080 dpi.

As seen in the table above, an imager with a resolution of 4800 dpi images at an output of 23,040,000 dpi pixels per dot per inch and a resolution of 5080 dpi images at an output of 25,806,000 dpi pixels per dot per inch. Compared to 4000 dpi, there’s up to over 60% more detail per surface area. This goes to show that the math of it all cannot be disputed. There is a significant difference between the resolutions of imagers that are 4000 dpi compared to 5080 dpi.

Operators that make use of imagers with a high dpi will be able to produce more intricate high-quality products that are no match to those of even slightly lower resolutions. Additionally, it is easier for press operators to come up to color, speed, and print with machines that have a high-resolution threshold, allowing customers to see a marked difference in the quality and detail of the products they are getting. “We were already above our competitors with 4800. Now, we are a step even higher at 5080, putting us at a greater advantage.”

Operators that make use of imagers with a high dpi will be able to produce more intricate high-quality products that are no match to those of even slightly lower resolutions. Additionally, it is easier for press operators to come up to color, speed, and print with machines that have a high-resolution threshold, allowing customers to see a marked difference in the quality and detail of the products they are getting. “We were already above our competitors with 4800. Now, we are a step even higher at 5080, putting us at a greater advantage.”

With the new XSYS and SCREEN digital imagers, Excelsior can handle anything and everything its customers need without issue. “Whether it be files of 5080, 4800, 4000, or 2540 dpi, the output will come out with crisp and clean resolutions.”

Operating with Efficiency

In the current flexographic market, nobody can compete with Excelsior. Where other shops have to operate from multiple locations, Excelsior is a centralized solution. “We can provide plates that can transfer ink better, give more density, 1-color job, 10-color job. We have a solution for everyone.”

Not only that but Excelsior has the ability to produce plates in a highly efficient manner. Excelsior prides itself on having multiple of the same high-quality equipment, which allows its team to experience improved capacities when it comes to printing plates. This allows Excelsior to create numerous plates at the same time, at every step of the process, to keep its operations moving smoothly. “Should we have a maintenance issue or breakdown, we would have enough capacity with equipment to not miss a beat.”

Excelsior has also invested in Quality Control so that its services can go beyond its printing capabilities. Its team has over 100 years of experience in the flexographic industry, combined. After working in the industry for so long, Excelsior’s team knows exactly what its customers are looking for and how it can improve each client’s operations. Not only that but Anderson & Vreeland also provided Excelsior with the latest analyzers, spectrophotometers, QC devices, and micrometers from Hybrid Software, GMG Color, X-Rite, and Betaflex so that Excelsior has all the necessary tools to make sure that each plate goes out at its optimum state. All these QC products contribute to the advanced consistency in quality, productivity, and cost savings that Excelsior experiences during the plate-making process due to the high measurement speed, accuracy, and ease of use that each product offers.

Through this intensive focus on Quality Assurance and Control, customers can rest assured that Excelsior’s plate manufacturing process will always be consistent with every plate it makes. Not only will every single plate print perfectly, but also each batch will be presented at maximum quality.

Through this intensive focus on Quality Assurance and Control, customers can rest assured that Excelsior’s plate manufacturing process will always be consistent with every plate it makes. Not only will every single plate print perfectly, but also each batch will be presented at maximum quality.

Continued Partnership with A&V

“It’s good to know we have a supplier that can provide us with the innovative ideas and advanced equipment to keep us and our customers on a cutting edge.”

Excelsior Marking continues to stay at the forefront of the flexographic industry thanks to its partnership with Anderson & Vreeland. With the latest press and plate-making equipment, Excelsior can streamline its processes and operations, allowing the company to become more efficient and productive across the board. Ready to improve your workflow operations? Contact us today to get started.