- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

What is Gravure Cell Analysis?

The Gravure Cell Analysis option for the AniCAM was developed for gravure printers where Quality Control of their gravure cylinders is desired. In particular for in-house recording of new roll data, roll condition during use, and to enable financial planning for refurbishing or replacement.

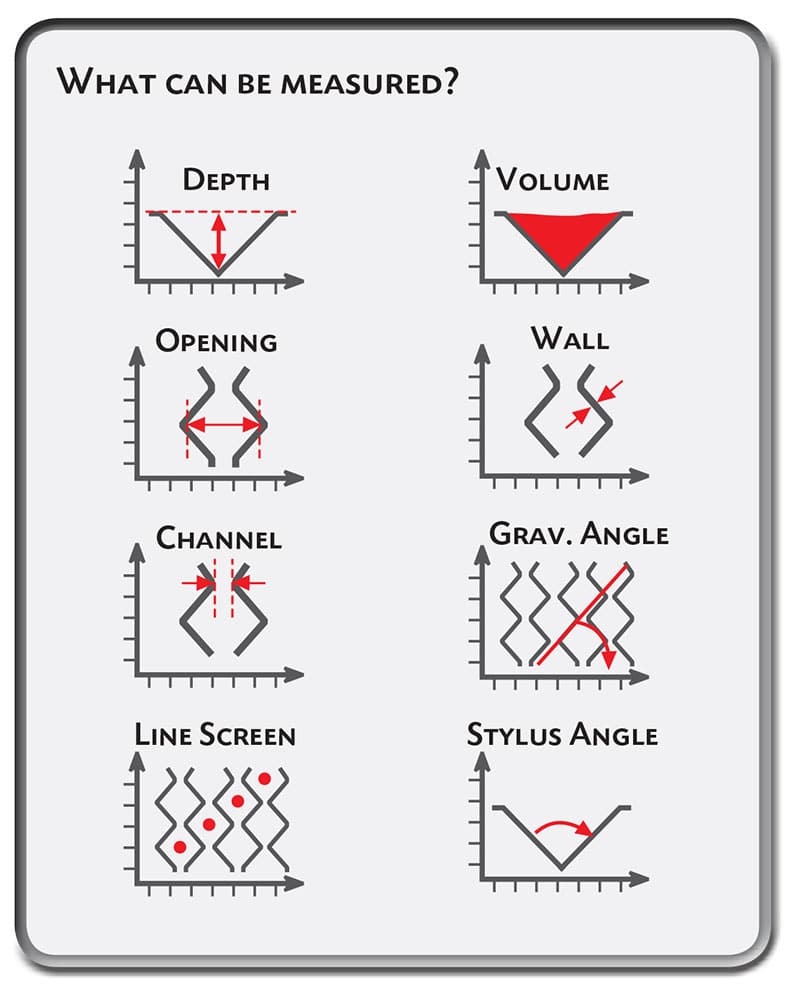

Practical internal management of Gravure inventory is desired to reduce color match time, ensure consistent print quality and highlighting potential issues before going to press by determining if a roll is clean or dirty. The measurement of cell volume, cell depth, channel, opening and wall width is needed to keep aware of roll condition and reduce the chance of lost production time and possibly material waste.

Key Benefits

- A very practical and easy to use tool that will ensure your gravure cylinders are properly identified with screen count, screen angle, cell opening, wall and channel measurements – all done in just a few minutes. Knowing the condition of your cylinders in the heart of your press, through proper identification and verification, gives increased assurance of the final printed result.

- All measurement information and images can be printed and/or exported for use in 3rd party software (like Excel or database programs) for comparison between historic and current information. You can now track the changes of your Gravure cylinders and monitor their condition.

More Benefits

- Being able to see if the cells are plugged or damaged – the AniCAM microscope will significantly help to reduce costly waste or reprints.

- The camera unit is very portable, therefore measurements can be taken in the press room or in the cylinder storage area making it a very practical all round tool for all print departments.

Electronic Archiving and Remote Viewing

Gravure Cell images can be archived and emailed. They are stored in their proprietary .gcp format which contains all measured values needed for retrieval and evaluation.

Additional QC Applications

Anilox Analysis for 2D and 3D measurement of Anilox rolls (volume, depth, wall width, opening, screen count, angle, distances etc.).

FlexoPlate Analysis for 2D and 3D measurement of flexo plates and sleeves (dot hight, percentage, screen count, profile, angle, distances etc.).

Easy to use and portable Scanning Microscope

The AniCAM 3D Scanning Microscope is a very professional instrument, it’s operation is really simple: To take a reading simply place the portable camera system on top of your gravure cylinder, select the appropriate setup and click the Cell Profile button. The image will then be transferred to the 2D/3D Analysis window, in which you select three or more cell areas – simply by clicking on the cells. The readings are then transferred to an Info section, where you enter the customer name, cylinder-ID and operator name. The system generates a report which can be printed or the data can be exported to a database or spreadsheet program for further analysis, such as your own reporting method for gravure cylinder wear analysis.

Why Gravure Cylinder Quality Control?

The Gravure Cell Analysis option for the AniCAM was developed for gravure printers where Quality Control of their gravure cylinders is desired. In particular for inhouse recording of new roll data, roll condition during use, and to enable financial planning for refurbishing or replacement.

Control of their gravure cylinders is desired. In particular for inhouse recording of new roll data, roll condition during use, and to enable financial planning for refurbishing or replacement.

Engravers

During the manufacturing process measuring of the actual opening, depth and volume on copper and subsequently chrome cells is becoming more important for quality control purposes. When engraving with styluses it is important to know their characteristics, including diamond shape and the way they are mounted in the holders. These variations can give considerably different real volume measurements which cannot be known when making theoretical calculations. Knowing the actual volume measurements can help in establishing better gamma print curves and consequently less press set up time. The difference in cell depth and volume before and after chroming can be quite considerable, which can be clearly seen when comparing the scanned copper and chromed visual information and numeric data. Establishing the differences can lead to improved chroming and reduced production issues

Printers

Using the Gravure QC application with the AniCAM 3D scanning microscope can help to establish the quantity of ink required for a job. The quality of refurbished or replaced cylinders can be compared to the original, important when establishing the characteristics for the print gamma. Cleaning of the cylinders and knowing that they have been properly cleaned and do not hold ink or varnish residue can save many hours of press set up time.