- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

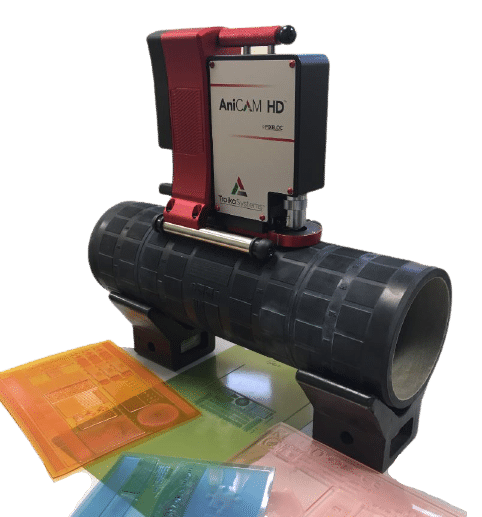

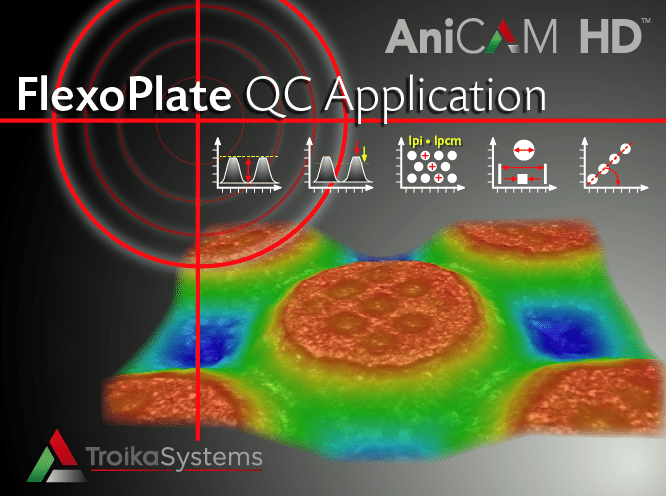

FlexoPlate QC

You will save on time, waste, and costs when you have full control over your flexo plates and sleeves.

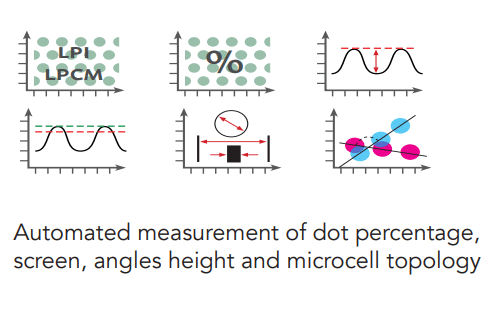

Two reading techniques are available with the AniCAM with Flexoplate QC: two-dimensional readings with automatic reflective or translucent dot detection and a three-dimensional analysis that provides additional information on dot shape, height, and relief depths.

Defective plates will waste time and money, lowering production and profitability. In the long run, cost savings from quality control on dot structure, relief, depth, and sizing can make a significant difference, for a quick return on investment.

The AniCam HD™ makes inspecting Anilox rolls quicker and with higher accuracy using the latest technology. Printers can keep track of their rolls and/or plates while saving money by reducing the amount of time and waste associated with press setup.