We Have Your (Sticky) Back

You may not think about sticky-back tape very much, but there’s more to this indispensable consumable of flexographic printing than is readily apparent. You probably know plenty about all the materials that are used in your operation but may not give much thought to sticky-back because it’s pretty much an out-of-sight and out-of-mind item. But that doesn’t mean it’s any less important to your day-to-day business operations. Picking the best tapes can pay off in greater productivity and profits.

You know from experience that tapes are anything but generic. Some hold plates well but take extra time to mount. Others bond so tightly that plates often tear when being removed. Knowing this, you may even automatically budget for new plates if a job will repeat in a couple of months. It might make a difference if you didn’t have to do that.

This week we’ll look at the new Pro-Series Cushion-Mount™ tapes from 3M™ with the Comply™ adhesive system that helps ensure the quality your customers expect.

Make Work Easier

Making flexo printing optimal, consistent and productive are the driving ideas behind the new Pro-Series Cushion-Mount™ tapes from 3M.

- Optimal means making sure you have the best possible tape for every job, whether it’s low density to maximize dot reproduction, high density for a solid color field or something in between.

- Consistent is ensuring a tape is the same thickness the entire length of a roll, or even when you use different rolls, so when you pull two samples, or a customer drops by for a press check, every label or package looks the same.

- Productive ensures a tape reliably performs the same way from mounting, throughout a run, through demounting to make sure your presses keep running.

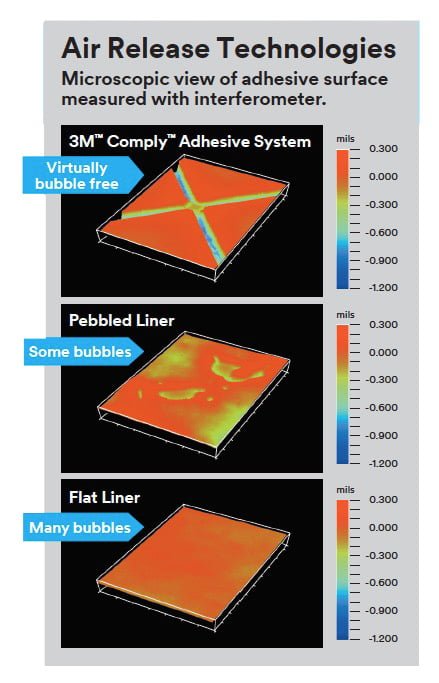

For example, peeling back the liner of the new 3M PRO-Series tapes reveals a unique cross-hatched pattern on the adhesive layer that offers the easy repositioning during initial application 3M tapes are known for, yet provides the same tenacious grip you need—especially along the edges—when pressed down with a roller during installation. The cross-hatched pattern automatically releases air bubbles as it is put down, reducing mounting time while requiring less force for removal than other 3M tapes. Ease of removal means your operators are more likely to be able to remove plates in one undamaged piece, letting you reuse plates and avoiding the time and expense of making new plates when a job is being rerun.

For example, peeling back the liner of the new 3M PRO-Series tapes reveals a unique cross-hatched pattern on the adhesive layer that offers the easy repositioning during initial application 3M tapes are known for, yet provides the same tenacious grip you need—especially along the edges—when pressed down with a roller during installation. The cross-hatched pattern automatically releases air bubbles as it is put down, reducing mounting time while requiring less force for removal than other 3M tapes. Ease of removal means your operators are more likely to be able to remove plates in one undamaged piece, letting you reuse plates and avoiding the time and expense of making new plates when a job is being rerun.

Anderson & Vreeland sells more sticky-back tape than any other flexo-focused supplier. Please contact us to discuss your needs so we can make sure the tapes you order are the right ones for your applications. No matter what your needs may be, our technical tape specialists are ready to help you find the exact tapes or other products that can help your business move forward.