Description

Printight P Type for Pad Printing

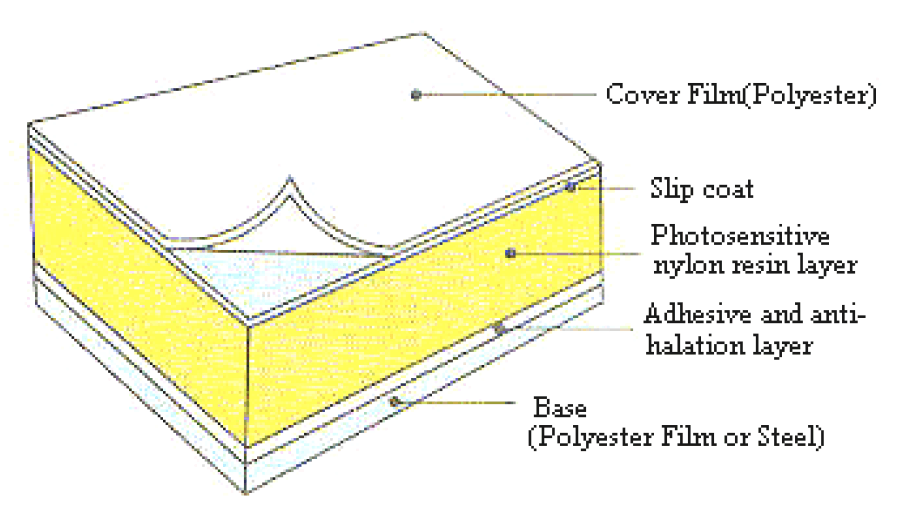

Photo-Sensitive Nylon Printing Plate

Advantages

- Easy processing: Possible to make plates in house due to easy and short processing.

- Water washable: No necessity of any solvent. Just water!

- High reproducibility: Allow to print very fine dots and lines. Our recommendation is to use 95%/300 lpi screen film.

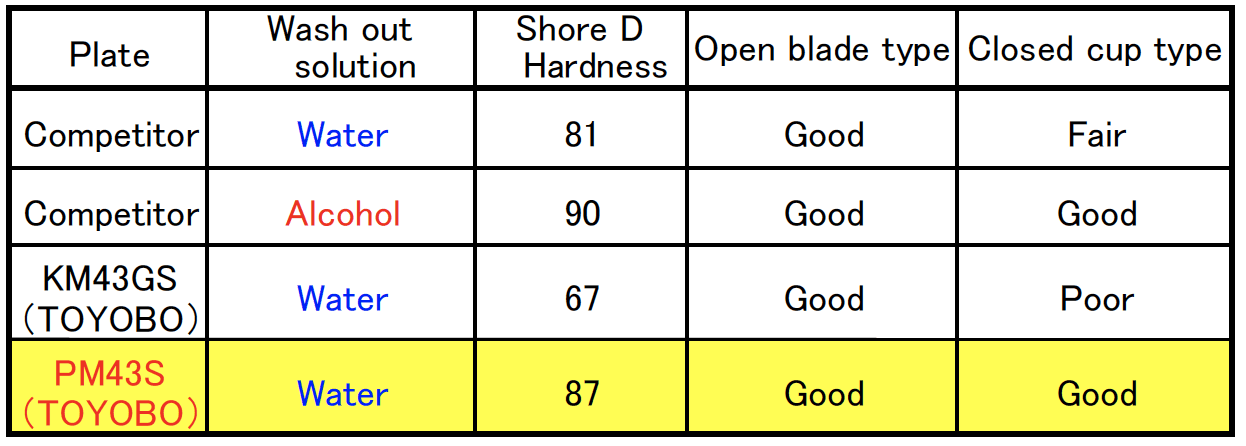

- High durability: Closed cup is available as well as doctor blade with excellent durability because of highly cross-linked photopolymer.

Comparison with other plates

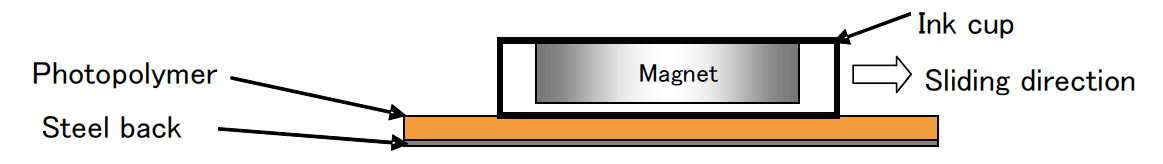

Testing method of sliding property of ink cup on the plate

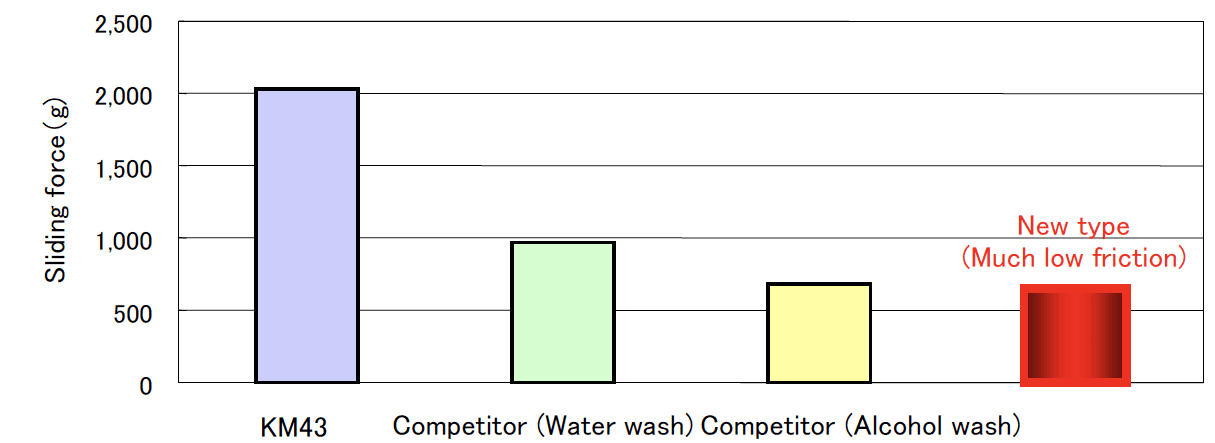

Comparison of sliding force of ink cup on the plate

How to use

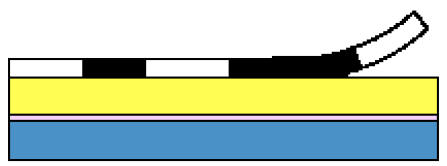

| 1.Contact with Positive film Remove cover film gently and place positive film on undeveloped plate. Use positive film having optical density of no less than 3.0. |

|

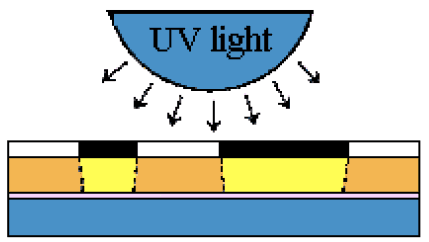

| 2.Exposure Expose plate,through positive film, to UV light having 360 nm wave lengths for 1-2 minutes. |

|

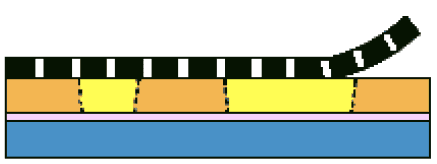

| 3.Contact with screen film Remove positive film and place screen film on undeveloped plate. 240 and 300 lpi screen films(tint) are available and are supplied by our distributor in your country. |

|

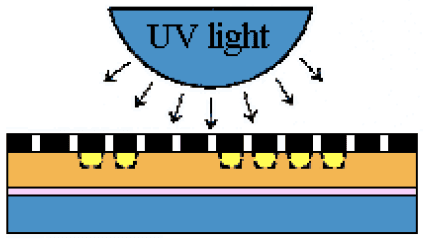

| 4.Exposure Expose plate,through screen film, to UV light having 360 nm wave lengths for 1-2 minutes. Give more exposure time, if a more shallow relief depth is required. |

|

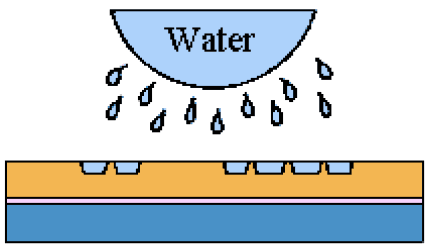

| 5.Wash-out Remove screen film. Wash-out exposed plate with water for 0.5-2 minutes. If wash out unit is not available, you can wash out the plate with running tap water. |

|

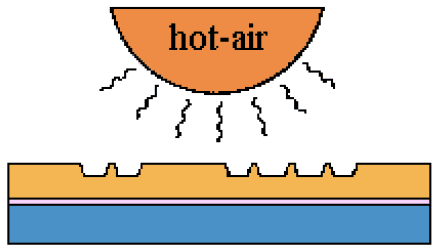

| 6.Drying Taking-off the surface water by sponge roll or compressed air. Dry the plate in a hot-air dryer for 5-10 minutes |

|

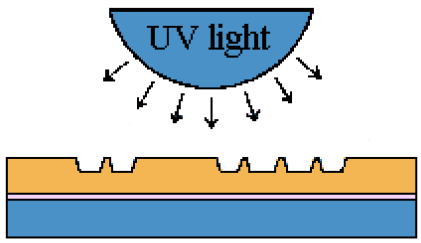

| 7.Post Exposure After washing-out, expose the developed plate again to UV light in order to get the polymer cured completely and strength for 5-10 minutes |

|