Description

INNOVATING THROUGH CUTTING-EDGE SOLUTIONS

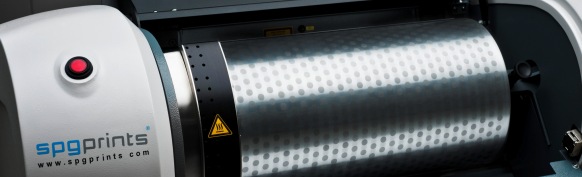

SPGPrints is the global leading provider of integrated solutions for rotary screen printing in the textile, label and industrial markets and has a leading position in digital printing. It offers complete printing systems as well as individual components (consumables) which ensures that it can deliver total systems solutions for customers.

With seventy years of experience, SPGPrints’ technology has proven itself in a variety of different markets and products such as fashion (clothing), home textile, labels, metallic ink on bank notes, wallpaper and decor printing. SPGPrints currently has 10 offices, with the company’s headquarters based in Boxmeer. Its manufacturing offices are located in the Netherlands, UK, Austria, Brazil, India and China. In total, it employs over 1,300 people worldwide.

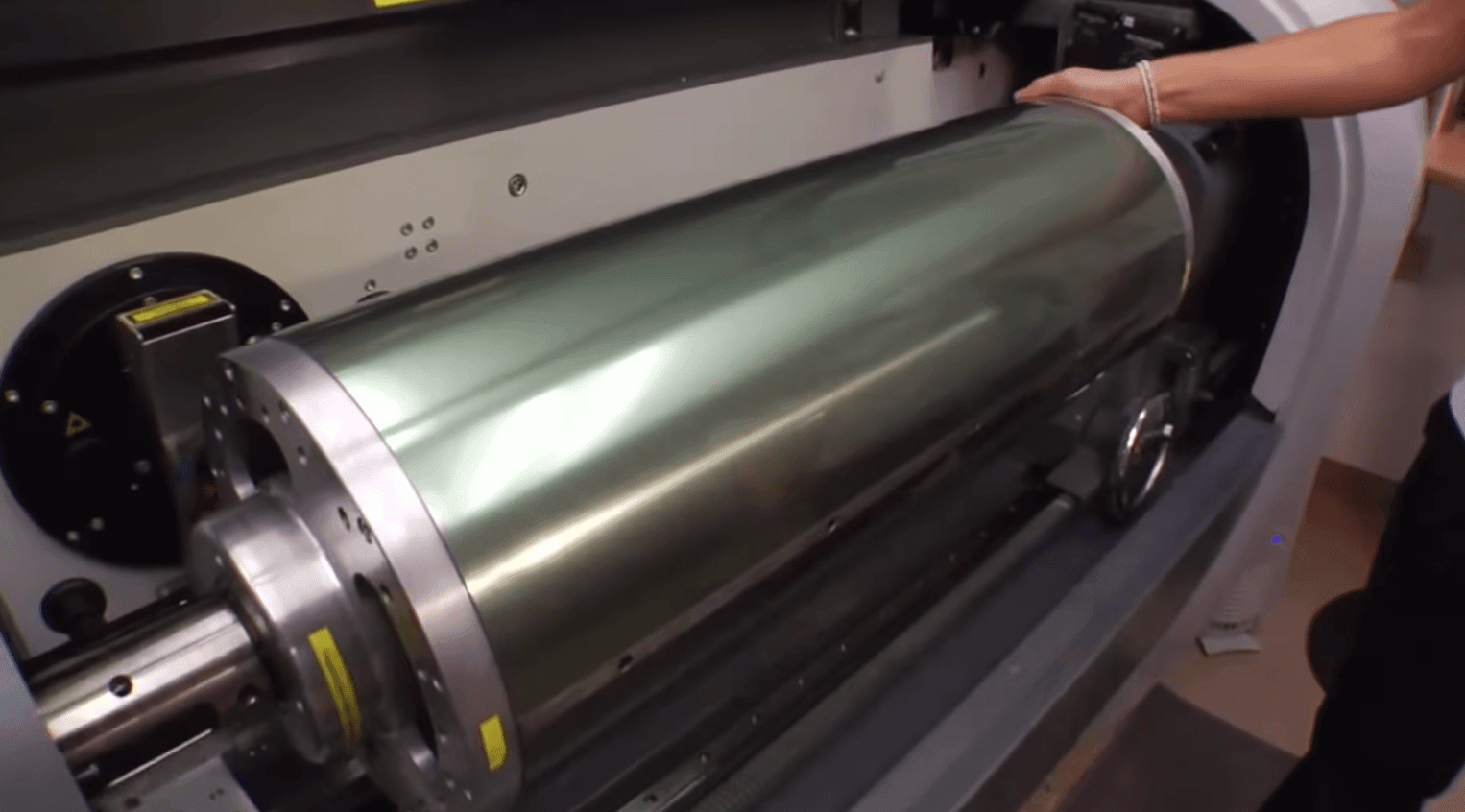

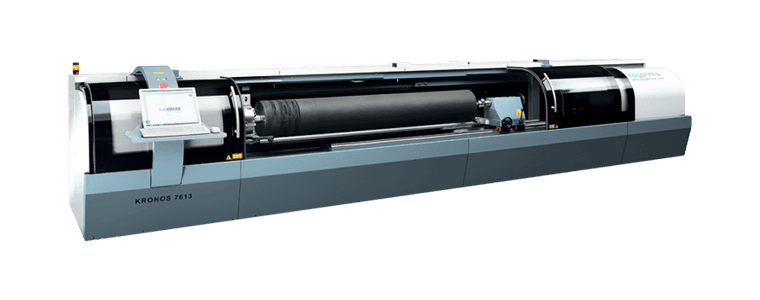

SPGPrints KRONOS Direct Laser Engraving

Direct Laser Engraver for seamless-endless sleeves and rollers

The KRONOS is SPGPrints ́ answer for companies who need seamless endless sleeves and rollers.

The unique laser system, developed in-house, allows top quality, even at higher relief depths, in order to meet today ́s and future requirements for elastomer sleeve making. The system is equipped with our own Active 3D® RIP software, which allows the direct imaging of various file formats. Like all prepress solutions from SPGPrints, the KRONOS is equipped with a digital database which stores different calibrated material specifications. This reduces the chance of human errors and increases the efficiency in the whole workflow. The system is designed to work with air cylinders in between 3-jaw chuck and center point.

Optional available accessories:

- Scan & Calibrate: sleeve surface measuring for quality check and semi-automated material calibration

- Rapid Removing: grinding of non-printing areas

- Various tooling like magnetic & vacuum drum

SPGPrints HELIOS Direct Laser Engraver

Direct Laser Engraving for polymer and elastomer

The HELIOS Direct Laser Engraving system is a proven solution for producing high quality printing forms for various applications. Different materials can be imaged, like polymer, elastomer, POM, etc. regardless of its color. Like every direct laser engraving system of SPGPrints, it uses database driven active 3D RIP system for relief printing forms in order to produce the optimal shoulders of the image. This results in excellent quality without special software tricks.The HELIOS allows a complete digital process with just one step. No solvent processing, no chemicals to be handled and stored. Dry offset and label printers can now produce the highest quality print with a shorter, simpler process with much less chance for errors. Overall response time is reduced for increased flexibility in meeting customer demands with no compromise in quality. Our laser systems are renowned for their stability and excellent reproducibility.

SPGPrints variLEX Direct Laser Exposer

Versatility has a new name.

Finally, the hybrid solution for digital pre-press is here. variLEX®, the new direct laser exposer for rotary screens, flexo and dry offset delivers top quality and an unmatched productivity. SPGPrints’ patented diode system unites perfect imaging quality with an unmatched versatility. The result, an excellent cost per screen or plate.

A digital exposer that matches your demands

The variLEX® is a versatile machine which can be configured according to your needs. It is possible to use the machine for different product applications, standard or high speed and different wavelengths. This gives you the versatility as an all-in one exposing unit matching your demands.

The variLEX® can be equipped for rotary screens, flexo and dry offset applications. The machine can be configured with high-power diodes. These diodes allow 2 different wavelenghts, which makes it possible to engrave black mask (polymer) material and also expose light sensitive layers, such as RotaPlate®. This is especially interesting for customers who use different printing technologies in their factory. The modular concept makes it also possible to extend the number of high power laser diodes in the machine, so that the machine’s productivity can help your company grow. Next to this, the machine can be equipped with a precision hybrid drum (magnet and vacuum), so that each plate or screen material from every supplier can be mounted and processed.

Quality

The variLEX® distincts itself by delivering an unmatched image quality. The machine is standard equipped with high definition optics. Next to this, for black mask engraving, the machine is standard delivered with our groundbreaking in-line UV-LED technology. This means that parallel with the imaging, the polymer material of the flexo or letterpress plate is directly exposed. The enhanced design of the UV-LED exposing ring ensures razor sharp images and high reproducibility. This fully controlled in-line UV technology reduces the workflow with a one-step process, and therefore saves time, improves the reproducibility and lowers the operating costs in your prepress department. This results in unmatched quality against lower costs for your plate and screen making.

Training and support

SPGPrints is already more than a decade active in pre-press equipment for the graphics industry. We are renowned for our excellent technical and application support. As global supplier we have a world-wide service network, which guarantees your need for local support. This all ensures that you have the maximum benefit from your pre-press department.