New Technology Enhances Performance at Allen-Bailey Tag & Label

Some packaging printers and converters always push the envelope with the latest software and equipment while others take a more measured approach. Both strategies are sound and can yield positive results for printers and their customers.

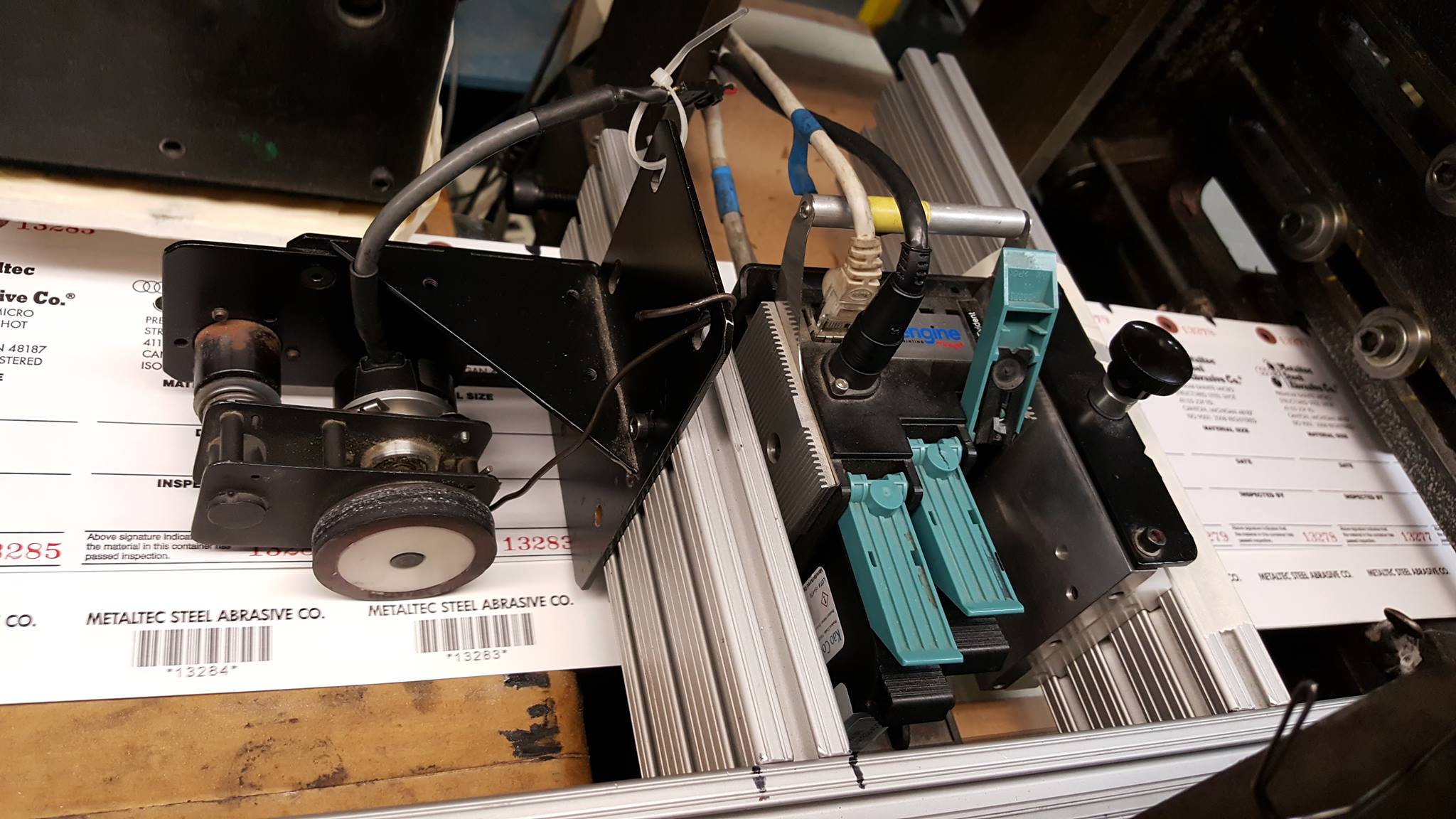

One company successfully taking the measured approach is Allen-Bailey Tag & Label, Inc., located in the small town of Caledonia, New York, about 25 miles southwest of Rochester. A 107-year-old firm, Allen-Bailey has a history of careful growth and thoughtful innovation, its latest being the acquisition of a new Xeikon ThermoflexX 20 platesetter. The new technology improves the quality of printing plates, reduces costs, and speeds production by eliminating time-consuming steps and increasing production capacity.

One company successfully taking the measured approach is Allen-Bailey Tag & Label, Inc., located in the small town of Caledonia, New York, about 25 miles southwest of Rochester. A 107-year-old firm, Allen-Bailey has a history of careful growth and thoughtful innovation, its latest being the acquisition of a new Xeikon ThermoflexX 20 platesetter. The new technology improves the quality of printing plates, reduces costs, and speeds production by eliminating time-consuming steps and increasing production capacity.

From outsourcing to insourcing

Allen-Bailey has operated independently for more than three decades, with a limited number of plates being produced off-site. But in a growing economy, Richard G. Phelps, Owner & Director of Marketing, knew it was time for a new strategy. “We are very optimistic in this rising economy and see positive activity across a many of our markets. Our customers are busy, growing, and eager to serve their customer base. Adopting state-of-the-art technology helps us meet their needs.”

Defining the challenge

To understand the needs of Allen-Bailey Tag & Label, its customers, and the company’s plans, Anderson & Vreeland’s Digital Business Analyst & Account Manager worked closely with Mr. Phelps to ensure they could recommend the optimal technology. Based on their analysis Xeikon ThermoflexX 20 was the best choice because it blended upgraded platemaking, integrated hardware, software, and a state-of-the-art workflow. Together, these enhanced the Allen-Bailey’s platemaking process, supported present day needs and helped position the company for the future.

Comprehensive implementation

Yet as anyone who has installed modern technology knows, sophisticated systems aren’t always plug and play. So to bring it all together, the Anderson & Vreeland Technologies Team and Xeikon worked closely with Allen-Bailey’s pre-press personnel to implement and install the new equipment in late 2017. The new system quickly became fully operational and the A&V Technologies Team continues providing training and system refinements to make every component as productive as possible.

““It took us a while to fully appreciate all the advantages the new platemaking technologies provide,” says Mr. Phelps. “Working with Anderson & Vreeland’s Business Team made all the difference for us. It ensured the new equipment was tailored for our needs, was integrated into our operation without disruption, and that our staff was trained on how to get the most out of it.”