Custom Labels Improves Quality and Production with Digital Platemaking

It was time to make a change. Peter Murphy, Creative Director of Custom Labels Inc. in Saskatoon, had experienced too many problems with their analog film processor and it was time to adopt digital platemaking. The film was jamming and we had to recalibrate the processor almost every time we used it, said Peter. It was time to replace the processor and we knew digital was the way to go. If we were going to advance we were going to go the whole way, he added.

Custom Labels is similar to a lot of narrow web shops that are considering transitioning to digital to remain competitive and offer improved quality. It is a family-owned organization with over 15 years of experience serving satisfied customers. The company serves a broad range of businesses and markets including packaging, beverages, pharmacy, chemical labels, health products, and more with four-color process and one-to-seven spot color printing.

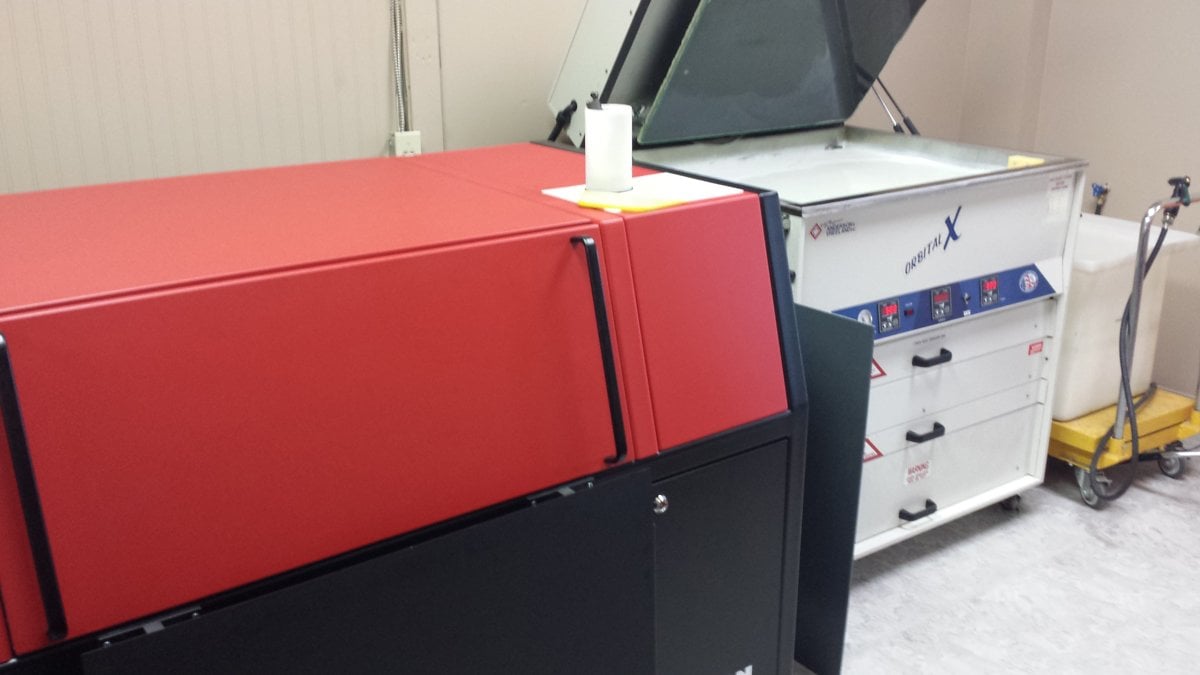

Once we decided to go digital, we looked at a few units but wanted to go with Xeikon’s ThermoFlexX 30 system offered by Anderson & Vreeland. We wanted to keep our LPI consistent and this was the best unit for the size of our plates, Peter observed.

Custom Labels has worked with A&V Canada for the last five years, which made the decision to transition to digital with A&V easier. Peter commented, We were comfortable working with Sean and A&V, and it’s nice to work with someone you know.

An important part of Custom Labels’ purchase was the testing and training provided by Anderson & Vreeland. Jessica Harkins Harrell, Technologies Manager for A&V, and Kenny Tucker, Technologies Specialists, worked on-site assisting with the installation of the ThermoFlexX platemaking system. Jessica’s team conducted press characterizations, established proper curves, and optimized the plate making to Custom Labels’ presses for maximum performance. Installation went smoothly. The staff was very knowledgeable and taught us very quickly. It only took two days for us to be familiar with the system, noted Peter.

An important part of Custom Labels’ purchase was the testing and training provided by Anderson & Vreeland. Jessica Harkins Harrell, Technologies Manager for A&V, and Kenny Tucker, Technologies Specialists, worked on-site assisting with the installation of the ThermoFlexX platemaking system. Jessica’s team conducted press characterizations, established proper curves, and optimized the plate making to Custom Labels’ presses for maximum performance. Installation went smoothly. The staff was very knowledgeable and taught us very quickly. It only took two days for us to be familiar with the system, noted Peter.

With regard to performance, the ThermoFlexX plate maker is the most productive imager on the market. Standard resolution is 2540 dpi, however, optional resolutions as high as 5080 dpi are available. Comprising leading-edge hardware and workflow software, this imager utilizes proven technology and open, modular digital-workflow solutions. Peter summed it up by saying, The ThermoFlexX is awesome. It has definitely made a big difference in production and the quality of our work. It makes it easier to set things up and reduces prepress time, but the improved quality is the main benefit.

Everyone loves a satisfied customer, so we are gratified that Custom Labels is pleased with the performance of their new digital platemaker as well as the support service and training provided by A&V Canada. On a 1 to 10 scale, I would rate A&V’s training and support services as a ‘10’. Everything went so smoothly. We would definitely work with A&V again when the need arises for new equipment or materials. We have good things to say about A&V, commented Peter.

I would like to thank Custom Labels and Peter Murphy for their business and for placing their trust in A&V Canada.