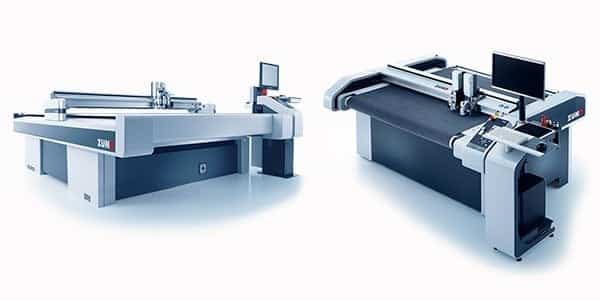

Zünd Cutting tables offer time-saving features and supercharged productivity

The New Year brings about fresh ideas and new approaches to applications. Take Zünd for example, the Swiss manufacturer of cutting systems recognized for innovation. Zünd’s pursuit of superior productivity in all aspects of digital cutting/finishing is truly impressive. Anderson & Vreeland has joined forces with Zünd to introduce their amazing cutting tables to the packaging industry.

The possibilities of Zünd cutters are endless: depending on size and model, you can process up to 3.2 m / 10 ft wide corrugated cardboard on the same machine that will cut 110 mm / 4.3 in packaging foam. High-performance tools crease and cut all commonly used packaging materials at quality levels that will blow away the competition. Zünd cutters let you complete all steps required in packaging production on one machine.

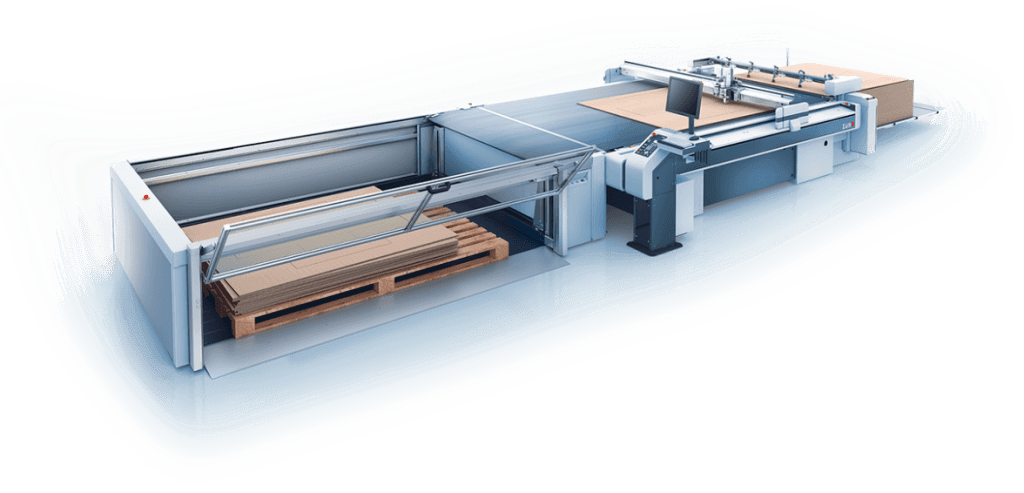

Custom production is a given in digital printing. Fully automated finishing with the Zünd Board Handling System represents the logical next step in a highly productive digital production workflow. Short or long runs, expect top quality at all levels in a die-less process with minimal personnel requirements.

From a tooling perspective, Zünd offers the following modules to name a few: High precision kiss-cutting with precise pressure control, marking and labeling with a variety of pen inserts, punch holes, and routing.

When we look at performance, Zünd has quite a few advantages over the competition. There are 10 varieties of table sizes for the G3 alone. Position accuracy is +/-0/1mm, most are at +/-.2-.3mm. Repeatability is at +/-.03mm, others are +/- .05 and higher. What is truly impressive is the weight, the G3 with the largest table is 1600kg, more then double the pack and for good reasons to maintain stability and eliminate any vibrations in the work area. While the competition offers standard vacuum zones, Zünd offers variable width driven by a 9 or 15kw turbine with auto adjust. With the vacuum design, the power consumption is next to nothing.

The modular design of Zünd cutting systems and their components allows for tailoring configurations to meet very specific production and automation needs.

To see and learn more, come take a look and see the difference at www.zund.com or www.andersonvreeland.com