The Power of Scalable Synergy

Building a first-class digital portfolio.

Synergy is what happens when distinct elements combine to create advantages for users. With label and package printing some of the best synergies combine traditional and digital technologies. Together they can help make a business more efficient and drive greater success and profitability. The challenge is picking elements the deliver the desired results.

At Anderson & Vreeland we select and work with partner companies to offer equipment and software that provide scalable synergies that help printers streamline operations while providing purposeful solutions to customers and brand owners.

The A&V digital portfolio

Our best example is the synergy that exists within the Anderson & Vreeland digital portfolio. The A&V Digital Group features a world-class collaboration that enables a streamlined solution from initial file preparation through the print and finishing process. The openness and complete array of options allow for A&V’s Business Analysts to customize solutions that accomplish the wide range of tasks involved with the synergy that drives profitability to the bottom line.

File processing

Begin with file prep using Hybrid Software’s CLOUDFLOW or PACKZ. CLOUDFLOW is a web-based, modular production workflow suite for file processing, asset management, soft proofing and workflow automation. Specifically built for the packaging graphics it supports PDF, color separation, trapping, screening, proofing, and much more. A key feature is Workspace, which indexes file repositories and stores information in a searchable database.

Begin with file prep using Hybrid Software’s CLOUDFLOW or PACKZ. CLOUDFLOW is a web-based, modular production workflow suite for file processing, asset management, soft proofing and workflow automation. Specifically built for the packaging graphics it supports PDF, color separation, trapping, screening, proofing, and much more. A key feature is Workspace, which indexes file repositories and stores information in a searchable database.

PACKZ is a native PDF editor specifically tailored for the packaging and graphics. It supports a modular production workflow for file processing, asset management, color separation, trapping, screening, proofing soft proofing and workflow automation.

Color management

Once your job goes through Hybrid’s tools, GMG Open Color provides accurate color management and separations that is specifically tailored to the needs of the packaging industry. For example, OpenColor enables accurate proof simulation of the overprinting effects of spot colors using special multichannel profiles.

Once your job goes through Hybrid’s tools, GMG Open Color provides accurate color management and separations that is specifically tailored to the needs of the packaging industry. For example, OpenColor enables accurate proof simulation of the overprinting effects of spot colors using special multichannel profiles.

Proofing, Printing and Plates

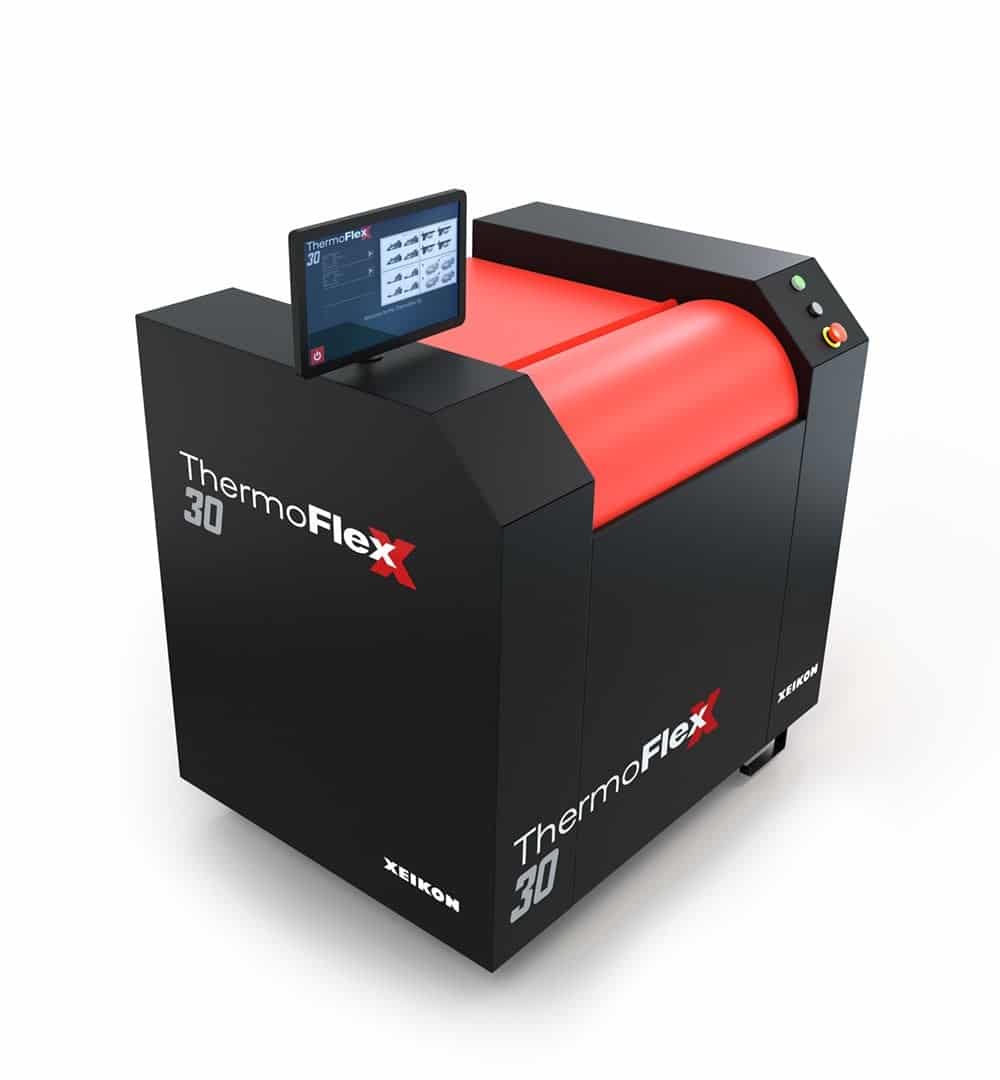

To make sure everything is accurate, proofing the file on an Epson S-Series or P-Series proofer before sending it to a digital press and/or a flexo press is the right device, make plates on a ThermoflexX platemaker using Flint Thermal plate materials. Whether you are producing tags, labels, flexible packaging, folding carton or corrugated packaging, digital presses and imagers, with resolutions up to 5,080 can do it all, as part of one continuous synergistic workflow.

To make sure everything is accurate, proofing the file on an Epson S-Series or P-Series proofer before sending it to a digital press and/or a flexo press is the right device, make plates on a ThermoflexX platemaker using Flint Thermal plate materials. Whether you are producing tags, labels, flexible packaging, folding carton or corrugated packaging, digital presses and imagers, with resolutions up to 5,080 can do it all, as part of one continuous synergistic workflow.

Cut and QC

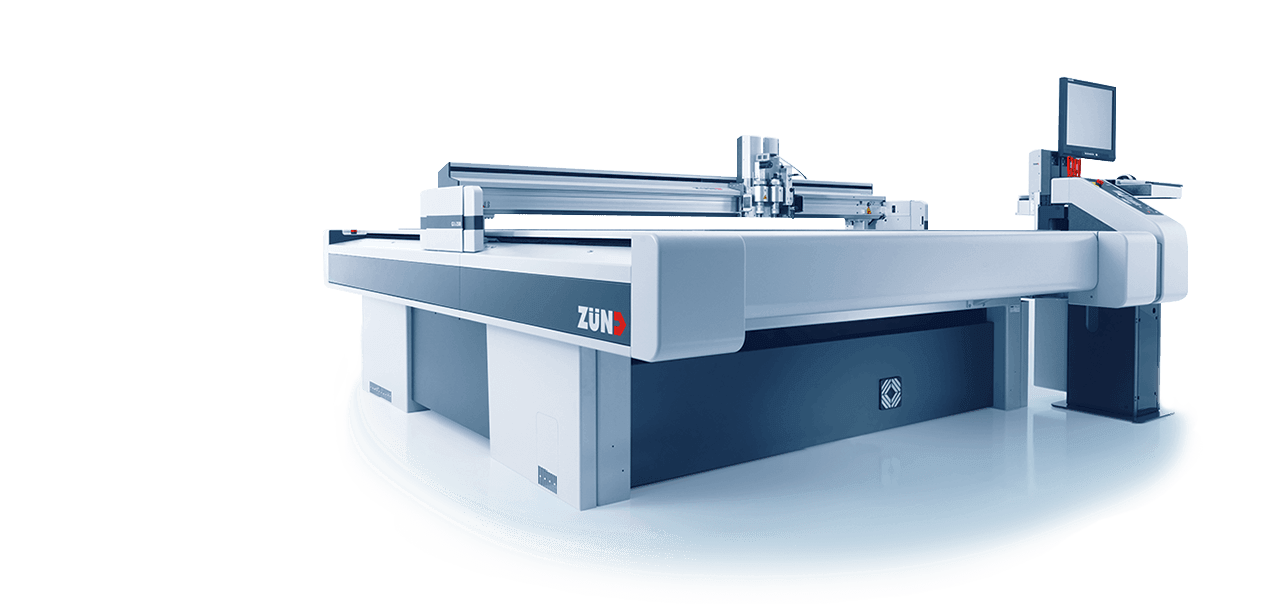

After printing the synergy keeps on going! Cut flexo plates on a Zünd digital cutting table before doing a final QC using X-Rite or Techkon devices.

From file input to shipping, Anderson & Vreeland and their partners provide a scalable synergy that helps ensure you satisfy customers and grow a profitable bottom line.

A Workflow that Works

The confluence of these products creates an end-to-end workflow for measuring and quantifying real time data to support multiple adjustments and corrections throughout the process to help ensure your labels and packaging match the expectations of your clients.

The partners described above offer compelling solutions that are unique in themselves and made more effective through the collaboration fostered by Anderson & Vreeland and the integration expertise of A&V’s Digital Group and Technologies Team.

Making the Workflow Work

No ‘out-of-box’ product suite or mix of equipment and software is an ideal fit for every label or packaging shop. There is no one-size-fits-all in label and package printing. So when questions arise or additional support is needed, the Anderson & Vreeland Digital Business Group is just a phone call away to guide you through any unexpected challenges.

A&V’s Technologies Team members are fully immersed in the products of these A&V partners, as well as other products throughout the industry. This accumulated knowledge allows A&V’s Technologies Team to address most questions and challenges concerning equipment and software selection, workflow, interactions between different products, then recommend and integrate those best-suited to individual operations. The solutions may include innovations that automate mission critical functions such as job submission, workflow, prepress, color management, platemaking, proofing, and digital or flexographic printing.

Because integrating equipment and software is complex, forward-looking support is a vital asset when building a workflow that blends traditional and digital activities. All Anderson & Vreeland Technologies Team members are FTA FIRST Implementation Specialist Level 3 Certified, with some members qualified in color management systems, including GMG, G7, GraCol and others. This broad expertise makes Technologies Team members a valuable resource for label and packaging printers seeking to address challenges before they occur, while they are happening, and helping them be better prepared to handle demanding new jobs in the future.

Because integrating equipment and software is complex, forward-looking support is a vital asset when building a workflow that blends traditional and digital activities. All Anderson & Vreeland Technologies Team members are FTA FIRST Implementation Specialist Level 3 Certified, with some members qualified in color management systems, including GMG, G7, GraCol and others. This broad expertise makes Technologies Team members a valuable resource for label and packaging printers seeking to address challenges before they occur, while they are happening, and helping them be better prepared to handle demanding new jobs in the future.

An Anderson & Vreeland sales professional or a Digital Business Analyst can show you how to leverage a customized range of equipment and software solutions that could foster greater productivity and profitability.

Contact Anderson & Vreeland to learn more about our products at info@andvre.com or 866.282.7697.