The Benefits of Cleaning Flexo Plates Automatically

With today’s demand for higher quality flexographic printing, the need to maintain clean plates and extend plate life has dramatically increased. A key factor in extending plate life for optimum print quality is maintenance, which will also save you money and the inconvenience that results from replacing damaged plates.

Results demonstrate that automatic plate cleaning systems reduce plate damage and offer superior consistency in cleaning, as opposed to manually cleaning flexo plates. Manually cleaning plates may cause damage due to excessive scrubbing or soaking plates for an extended time to remove dried ink deposits. It is virtually impossible to manually clean plates so they are exactly the same after repeated use.

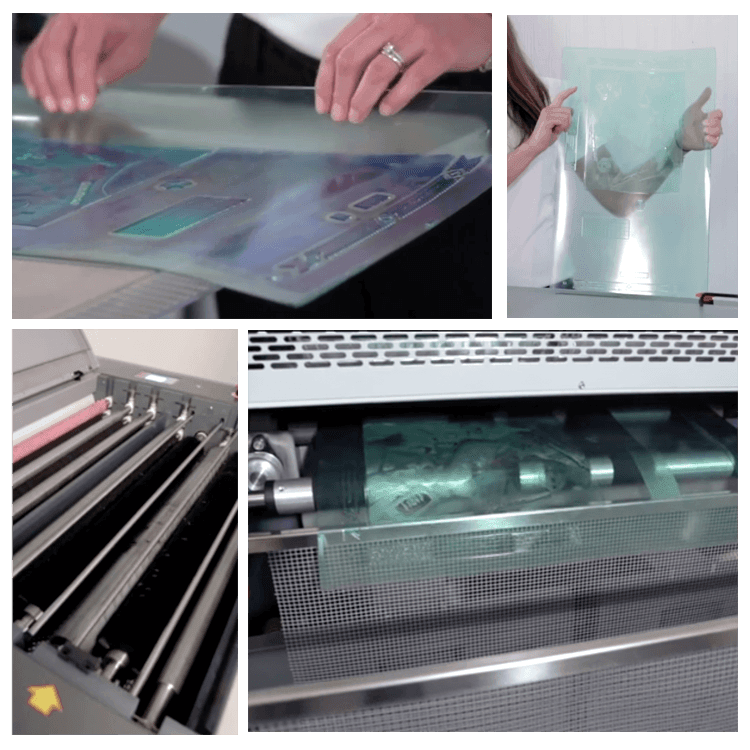

Flexo Matic automatic plate washers offer excellent cleaning capability for hard to clean reverse areas and screens, and offer unsurpassed consistency in cleaning so plates remain in the same top condition, time and again. These plate washers clean every kind of ink from the complete plate surface with liquid detergent and two rotating, translational brushes.

“You can now clean, rinse, and dry flexo plates much quicker, more effectively, and consistently with a Flexo Matic plate washer. You simply feed plates into the system and they are cleaned and dried automatically, and ready for storage,” noted Jessica Harkins Harrell, Technologies Manager for Anderson & Vreeland, Inc.

Environmental benefits of Flexo Matic plate washers include extending the life of flexo plates for repeated use, and recycling the plate washing liquid and rinse water that provides for extended use. These plate washers also assist with compliance of safety rules for the operator and environment since they automate the process of cleaning and drying flexographic plates.

Watch the video showing the automated flexo plate cleaning process with a Flexo Matic plate washer and decide for yourself: