Taking the Next Step with Digital Plates

Vice President Jason Hynes and the ATL Corp. team in Menomonee Falls, WI knew what they needed to do to take their flexographic printing business to the next level. ATL started as a printing shop in 1954 and over the years grew into a full-service printing and material converting company. “Recently, we have been focused more on the converting part of our business – die cutting, laminating, island placement, etc. We recognized that to take our flexographic label printing business to the next level, we needed to invest in the latest technology – for us, the first step was to upgrade to a digital platemaking system.”

Vice President Jason Hynes and the ATL Corp. team in Menomonee Falls, WI knew what they needed to do to take their flexographic printing business to the next level. ATL started as a printing shop in 1954 and over the years grew into a full-service printing and material converting company. “Recently, we have been focused more on the converting part of our business – die cutting, laminating, island placement, etc. We recognized that to take our flexographic label printing business to the next level, we needed to invest in the latest technology – for us, the first step was to upgrade to a digital platemaking system.”

Where to start?

ATL’s platemaking system was solid but was not delivering a level of print quality that sophisticated customers required. “Really, the main issue was about achieving a higher quality level,” says Mr. Hynes. Often, ATL had to outsource the making of flexo plates instead of building them in-house, which meant higher costs and longer lead-times.

As ATL began looking for ways to upgrade their platemaking system, they were approached by Anderson & Vreeland. ATL had worked with A&V before but had only purchased basic consumables. It wasn’t until they “opened the cupboard,” as Mr. Hynes puts it, that they realized the competitive advantage they could gain by deepening their relationship with A&V. Mr. Hynes recalls, “We did a great deal of research and did our due diligence when searching for a partner to work with us as we started to transform our business and all the feedback pointed us to A&V” From simple accessories and consumables to digital solutions, A&V’s vast digital portfolio addressed the specific needs of ATL.

Fast Response and Depth of Support

A critical part of ATL’s decision to partner with A&V was the fast response and depth of support – right from the get-go. During ATL’s research phase, A&V was the quickest to respond with quotes and follow-up meetings. Within a week on initial inquiry, A&V’s Digital Business Analyst Jeff Skolnik, several from the A&V Business Solutions Group, and James Van Buskirk of XSYS met at ATL to hammer out the details of how A&V could support ATL’s pursuit of a new digital platemaking system. And when ATL’s Pre-Press & Art Director, Carissa Tesch, needed help laying out their new plateroom, A&V developed and delivered drawings and plans within 48 hours. Mr. Hynes says, “That was when we realized that we really had a partner in A&V.”

A critical part of ATL’s decision to partner with A&V was the fast response and depth of support – right from the get-go. During ATL’s research phase, A&V was the quickest to respond with quotes and follow-up meetings. Within a week on initial inquiry, A&V’s Digital Business Analyst Jeff Skolnik, several from the A&V Business Solutions Group, and James Van Buskirk of XSYS met at ATL to hammer out the details of how A&V could support ATL’s pursuit of a new digital platemaking system. And when ATL’s Pre-Press & Art Director, Carissa Tesch, needed help laying out their new plateroom, A&V developed and delivered drawings and plans within 48 hours. Mr. Hynes says, “That was when we realized that we really had a partner in A&V.”

XSYS nyloflex Xpress Thermal Processing System

But what further solidified ATL’s decision to go with A&V was the on-going support and education ATL received. As a global printing, converting, and contract manufacturer, ATL only knew the customers and markets they currently served. ATL needed a partner, an extension of their business, that could guide them to and help them implement the best technology in digital platemaking. “We were seeking a partner that could bring all that together – from art to part – and that’s exactly what A&V did“, says Jason Hynes. As an industry expert, A&V and their digital portfolio provided a high degree of support and education that ATL could not find elsewhere. A&V acted as an educator and consultant, consistently guiding ATL towards the best solutions that would complement their needs. “What A&V continues to do is educate and provide the knowledge and solutions,” says Ms. Tesch. “And I think this will be A&V’s key to continued growth with us.”

Taking ATL to the Next Level

In less than six months, ATL was equipped with a new ThermoflexX Digital Platemaker, known for its industry-leading 5,080 dpi resolution; Front-End Software for preparing files for platemaking; a XSYS nyloflex® Xpress Thermal Processing System; Ovit plate washer; and all the other equipment needed to get ATL running on latest technology.

From left to right clockwise: ThermoflexX 30 Digital Platemaker – AV Xpose 2530 Exposure Unit – Flint nyloflex® Xpress Thermal Processing System – Ovit plate washer

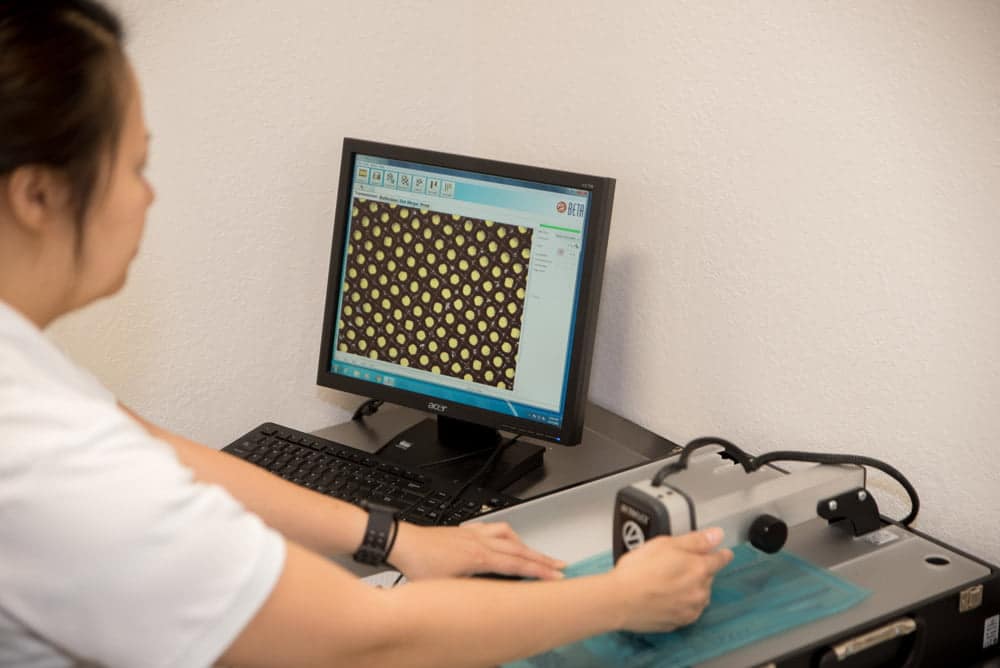

Once the new digital platemaking system was up and running, the ATL team immediately noticed the higher resolution of prints coming off their presses. With the ThermoflexX imaging plates at 5,080 dpi and 150 lpi resolution, their presses were printing clearer images with better definition, sharper lettering and types, and higher line rulings. ATL was able to raise the bar on what they were offering their customers by simply giving their existing printing presses a better front end and platemaking system.

Internally, ATL saw quicker turn arounds for plate production. With ThermoflexX and its automatic plate loading and auto-feed, ATL was producing plates in less than half the time it originally took. In addition, their new platemaking process required less human handling and, thus, made the entire process easily scalable, which was an important component to ATL’s growth.

The faster, easier loading and consistent, repeatable imaging of the ThermoflexX digital platemaker allowed ATL to increase the output of their presses. ATL was able to complete more jobs per shift, reduce turnaround time for customers, and offer competitive pricing. But better pricing was not the only benefit the customers valued. “Our customers really value print quality. We’ve always been a quality-focused company, and this new equipment really brought us to a new level,” says Mr. Hynes. “This platemaking system that’s connects with our presses will help us grow into other markets, no question about it.”

A Deeper Partnership

ATL’s partnership with A&V is just getting started. ATL plans to deepen their partnership with A&V in the upcoming months as they bring on another new, flexographic printing press to support the growth of their business. “We are excited to be a part of ATL’s growth,” says Jeff Skolnik. “This long-term partnership will help solidify strength and visibility of who ATL is within the industry. The opportunity to provide the technology advances within our industry from our world-class partners, while serving ATL with our own vast resources of support, is who we are and what A&V is all about.“