Canada Case Study: Supremex

Life’s Hardest Questions?

- Window or Aisle?

- Coke or Pepsi?

- Solvent plates or Water wash?

So here’s the thing. Solvent costs you money when you use it, store it, and send it out for recycling. Then when you get it back you have to mix it with fresh solvent before using it for the next wash down. Water changes the game by eliminating these steps, giving you and your team better control over the wash out process while helping raise your company’s environmental profile.

![]() At SupremeX, the largest Canadian-based provider of packaging and envelopes, the combination of costs, time, and environmental concerns drove the company to make the move to a water-wash system. “We had been looking at the problems of our solvent wash plates for several years, looking for the right solution,” recounts Dennis Prosper, Pre-Press Manager at SupremeX. “Some of the solvents we used bordered on being carcinogenic, so we needed a process that was safer for our people and for the environment. In talking with different companies, we realized Anderson & Vreeland’s expertise with the equipment and their knowledge of flexo was very important in helping us make the decision.”

At SupremeX, the largest Canadian-based provider of packaging and envelopes, the combination of costs, time, and environmental concerns drove the company to make the move to a water-wash system. “We had been looking at the problems of our solvent wash plates for several years, looking for the right solution,” recounts Dennis Prosper, Pre-Press Manager at SupremeX. “Some of the solvents we used bordered on being carcinogenic, so we needed a process that was safer for our people and for the environment. In talking with different companies, we realized Anderson & Vreeland’s expertise with the equipment and their knowledge of flexo was very important in helping us make the decision.”

Costly and inefficient

SupremeX found the escalating environmental and financial costs of handling solvents a burden and sought an alternative approach that was environmentally sound. “It could take a month to accumulate enough used solvent to send out for recycling and there was still a 5 to 1 ratio of old to new solvent,” explains Prosper. “New solvents are expensive, and it could take a month before recycled solvent was returned. It just was a costly and inefficient process that was a place where we could gain productivity.”

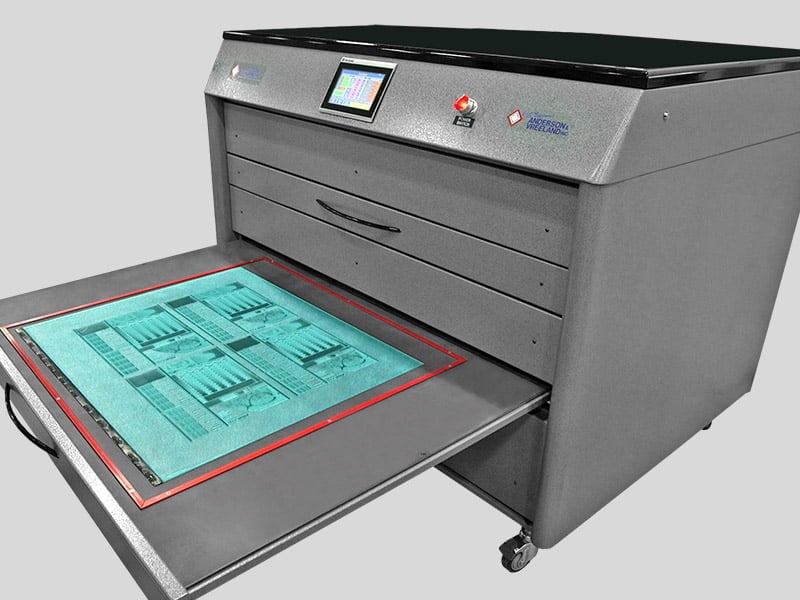

Shifting to water wash was the answer because it let SupremeX move toward elimination of solvents in all its facilities. But the switch has not been instantaneous. The new systems are made by Anderson & Vreeland, shipped to Canada, then installed, with each facility requiring a unique installation.

Weekend work

The customization was the responsibility of AV Technical Sales Team of Richard Heaps and Martin Schofield. “We have installed so many Orbital and Whirl A Way units that they now go in quickly and easily, with little if any interruption to production,” recounts Schofield. “The challenge was decommissioning the solvent system, removing it and installing our water processor and the polymer reclaim Whirl A Way system, all without interrupting a high volume, high output shop like the Toronto and Montreal SupremeX facilities“.

The customization was the responsibility of AV Technical Sales Team of Richard Heaps and Martin Schofield. “We have installed so many Orbital and Whirl A Way units that they now go in quickly and easily, with little if any interruption to production,” recounts Schofield. “The challenge was decommissioning the solvent system, removing it and installing our water processor and the polymer reclaim Whirl A Way system, all without interrupting a high volume, high output shop like the Toronto and Montreal SupremeX facilities“.

“Richard and Martin actually came in on weekends to work with our team and minimize downtime,“, says Prosper. “The water wash machines require some on-site assembly and because each installation was customized. Richard, Martin, and the Anderson & Vreeland Technical Team made sure each machine was properly configured so it would run as needed.”

After the Toronto location was up and running with two Orbital plate processors, two Whirl A Way polymer reclaim systems and the new AVXpose unit, they did it all over again in the Montreal facility.

This was one of the larger installations we have done, with lots of potential pitfalls and obstacles,” says Sean Sawa, Director of Sales for Anderson Vreeland Canada. “But with Richard, Martin, and Jessica Harrell from our U.S.-based Technology Team, as well as a high level of support from SupremeX, the entire process was seamless, painless and fast.“