Resolution Matters!

The human eye and brain are hard-wired to be highly selective, right down to the elements of a label or package that influence purchase decisions. Some of those details are tied to image sharpness and clarity, so more resolution is almost always a good thing. Knowing this, brand managers seeking to make sure their products stand out on retail shelves insist on superior print quality on labels, flexible packaging, or folding cartons. And with flexography, that quality starts with imaging the plates.

No longer second-rate

Only a few years back many commercial printers sneered at flexo as second-rate printing. They said flexography couldn’t provide the fine detail in highlights, shadow, and in vignettes as offset printed work. That was true, but it was before flexographic plates became a product of digital production techniques.

Now, a walk down the aisles of any retailer shows how all types of flexo-printed products take full advantage of the “three-foot effect”, that moment of engagement based on sheer eye appeal. It rests on clearer, sharper text and images that grab shoppers’ attention by bringing out details that once were missing. And the best flexo systems deliver. But there is a problem.

Resolution: Some is good. More is better

Many plate imagers in use today are limited to 2400 or 2450 dpi resolution, an old standard that worked for years. This can be adequate for a shrinking range of applications, even as brand owners insist on higher image quality. Although some imagers can offer 4000 or 4800 dpi, they rely on proprietary workflows that place limits on how jobs can be accepted and processed. This works for some converters, but savvy converters want fewer limitations, seek more versatility, and want integrated plate production solutions.

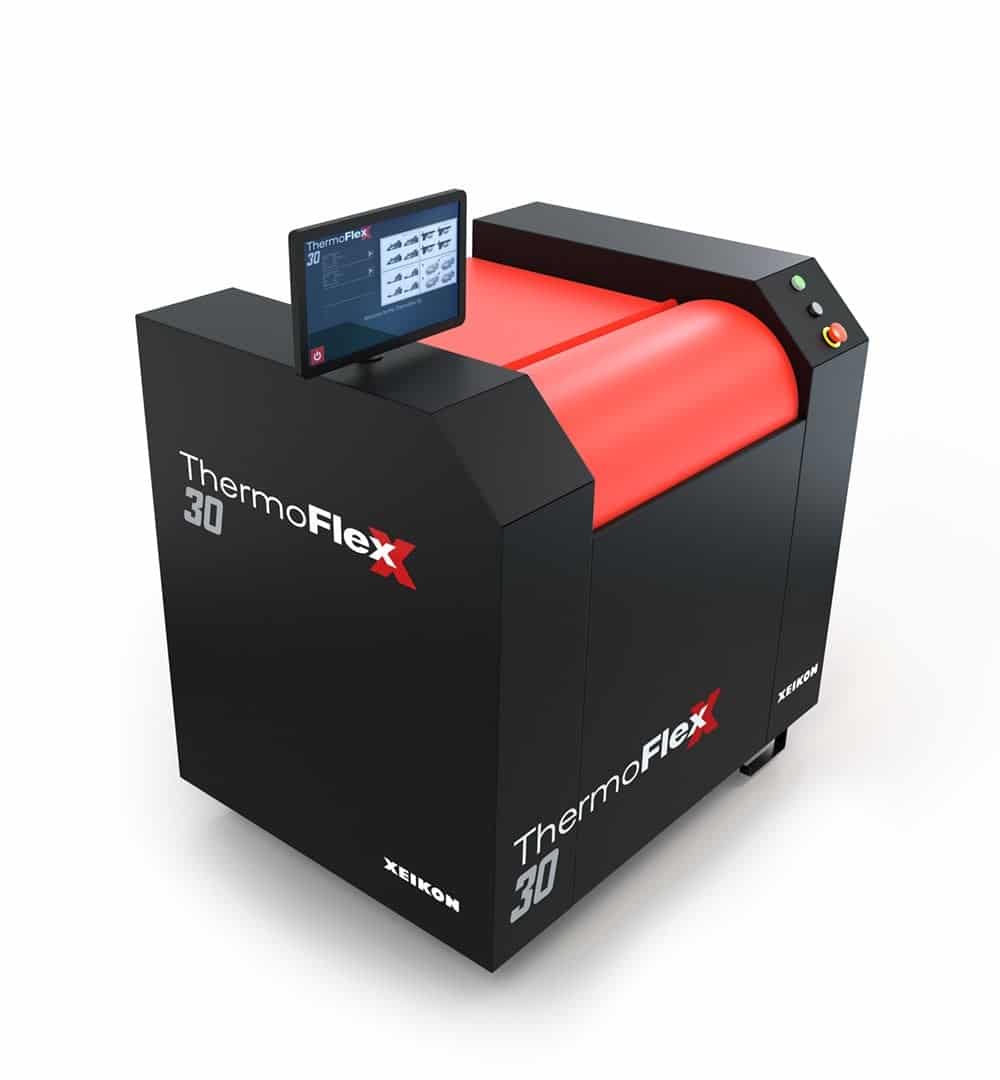

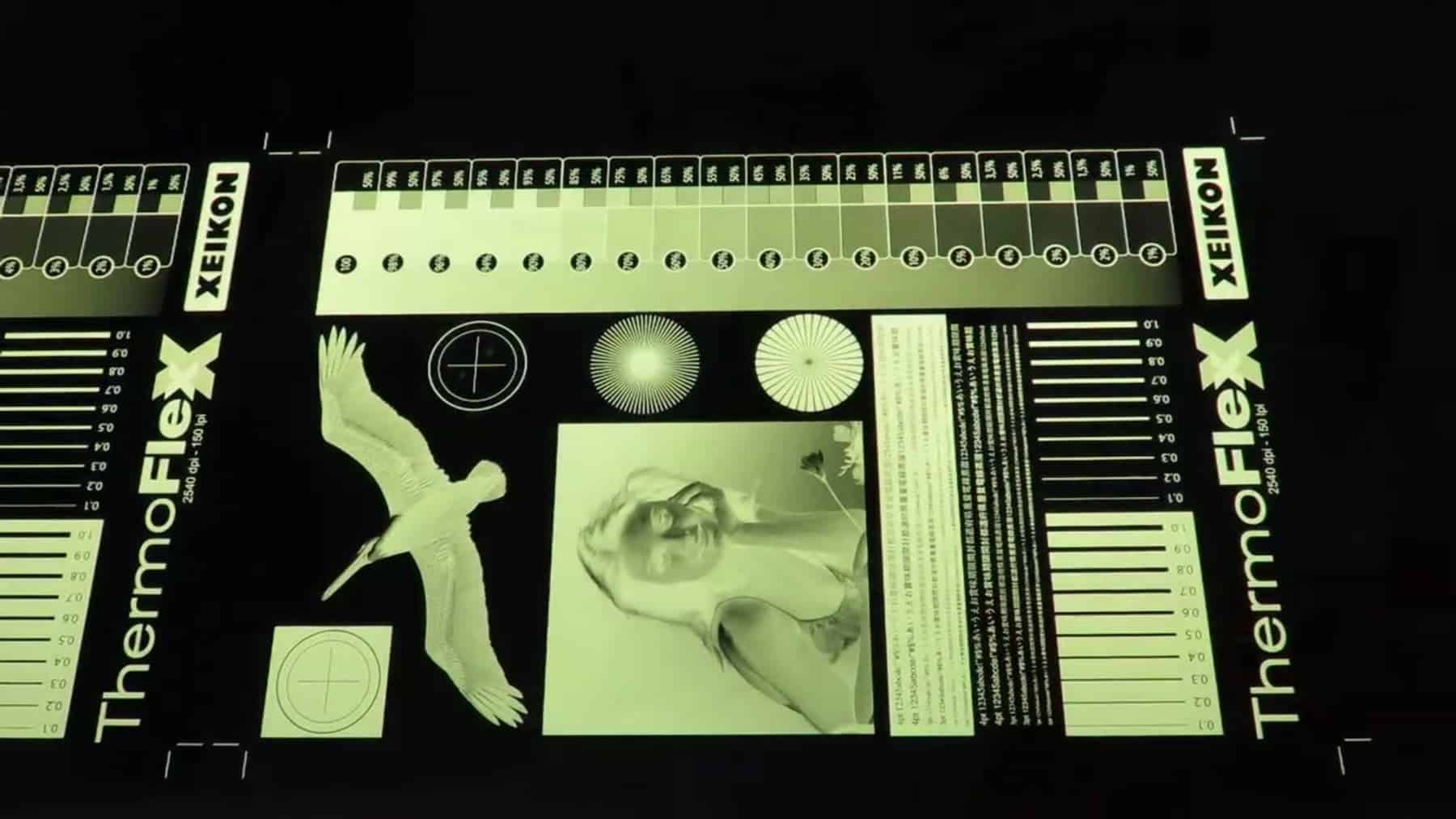

Such is the thinking that drives the ThermoFlexX 20, 30, 48, 60, and 80 models from Xeikon. The ThermoflexX line combines open, modular digital-workflow solutions with leading-edge hardware, workflow software, and proven surface screening technology. This helps customers produce high-quality digital flexographic and letterpress plates at up to five resolutions in a single machine, from legacy 2400 dpi to the latest 5080 dpi (equal to 645 gray levels at 200 lpi) for crisp text and unparalleled detail. This helps ensure smooth tonal gradations and sharp vignettes that generates the three-foot-effect that “provides “pop” on retail shelves.

Such is the thinking that drives the ThermoFlexX 20, 30, 48, 60, and 80 models from Xeikon. The ThermoflexX line combines open, modular digital-workflow solutions with leading-edge hardware, workflow software, and proven surface screening technology. This helps customers produce high-quality digital flexographic and letterpress plates at up to five resolutions in a single machine, from legacy 2400 dpi to the latest 5080 dpi (equal to 645 gray levels at 200 lpi) for crisp text and unparalleled detail. This helps ensure smooth tonal gradations and sharp vignettes that generates the three-foot-effect that “provides “pop” on retail shelves.

Imaging & processing integration

Helping achieve this quality is the integration of Xeikon ThermoflexX with processing technologies from Flint Group. For instance, plate materials designed for the Flint nyloflex® Xpress thermal plate processor can be imaged on a ThermoflexX imager. This provides a streamlined workflow that delivers the best quality plates to your flexo press. To ease the fit into virtually any converter’s operation, all ThermoFlexX imagers accept 1-bit TIFF files generated by any workflow, RIP, or front-end as well as hybrid or surface screens. ThermoFlexX imagers can also expose plates that use a LAM layer as well as Gallus Screeny (digital screen) and ablative films. This, plus innovative and easy to use features for plate handling make the ThermoflexX line of imagers an easily integrated choice for any busy shop where image and print quality are critical deliverables.

Plate Imaging with the ThemoFlexX 30

To find out more about how you can achieve optimal image quality on all types of labels and packaging, ask Anderson & Vreeland how ThermoflexX Imagers can deliver the quality brand owners are looking for and help ensure shoppers’ attention at retail.

Learn More About ThermoFlexX>> This post is part 3 of our Digital Portfolio series. To learn more about the entire workflow, check out our spread in the November edition of Flexo Magazine.

>> Read Part 1 on Hybrid Software

>> Read Part 2 on GMG Color