Keeping Pace. With Change.

Darin Lyon – President & CEO

Change is everywhere you look. It’s part of the time we live in.

For much of Anderson & Vreeland’s 56-year history advances in our industry occurred gradually. There was time to consider, accept, and adapt to emerging technologies and new ways of thinking. But now, like much of life, the pace of change has become frenetic, forcing the adoption of new ideas, equipment, and processes.

At A&V we look at change as an opportunity to make strategic moves that can foster growth and success. Change is part of an ongoing conversation we have with all our customers and is part of the relentless energy that drives our industry forward. Within this, two advances are especially important.

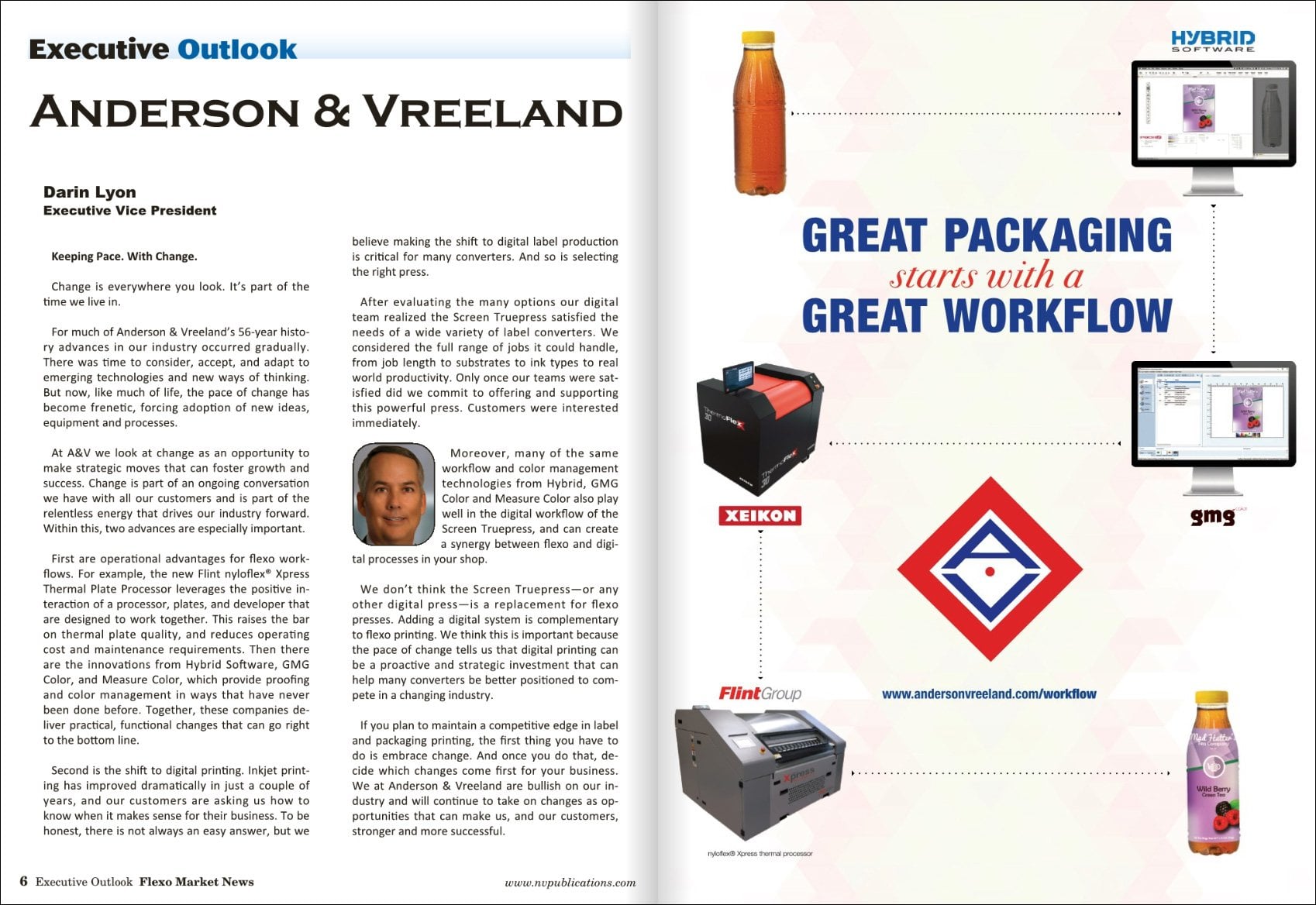

First are operational advantages for flexo workflows. For example, the new Flint nyloflex® Xpress Thermal Plate Processor leverages the positive interaction of a processor, plates, and developer that are designed to work together. This raises the bar on thermal plate quality, and reduces operating cost and maintenance requirements. Then there are the innovations from Hybrid Software, GMG Color, and Measure Color, which provide proofing and color management in ways that have never been done before. Together, these companies deliver practical, functional changes that can go right to the bottom line.

Second is the shift to digital printing. Inkjet printing has improved dramatically in just a couple of years and our customers are asking us how to know when it makes sense for their business. To be honest, there is not always an easy answer, but we believe making the shift to digital label production is critical for many converters. And so is selecting the right press.

After evaluating the many options our digital team realized the Screen Truepress satisfied the needs of a wide variety of label converters. We considered the full range of jobs it could handle, from job length to substrates to ink types to real-world productivity. Only once our teams were satisfied did we commit to offering and supporting this powerful press. Customers were interested immediately.

Moreover, many of the same workflow and color management technologies from Hybrid, GMG Color, and Measure Color also play well in the digital workflow of the Screen Truepress and can create a synergy between flexo and digital processes in your shop.

We don’t think the Screen Truepress—or any other digital press—is a replacement for flexo presses. Adding a digital system is complimentary to flexo printing. We think this is important because the pace of change tells us that digital printing can be a proactive strategic investment that can help many converters be better positioned to compete in a changing industry.

If you plan to maintain a competitive edge in label and packaging printing the first thing you have to do is embrace change. And once you do that, decide which changes come first for your business. We at Anderson & Vreeland are bullish on our industry and will continue to take on changes as opportunities that can make us, and our customers, stronger and more successful.

This article originally appeared in the 2017 Executive Outlook edition of Flexo Market News.