Case Study: Bison Bag

Bison Bag is a flexible plastic packaging company headquartered in Lockport, New York, that has provided its customers with high-quality packaging for a wide assortment of products for over 50 years. Bison Bag has established itself as a leader in the manufacturing of value-added flexible packaging. They own four printing presses, two laminators, three slitters, along with other converting equipment.

The Path to Smart Inventory Control

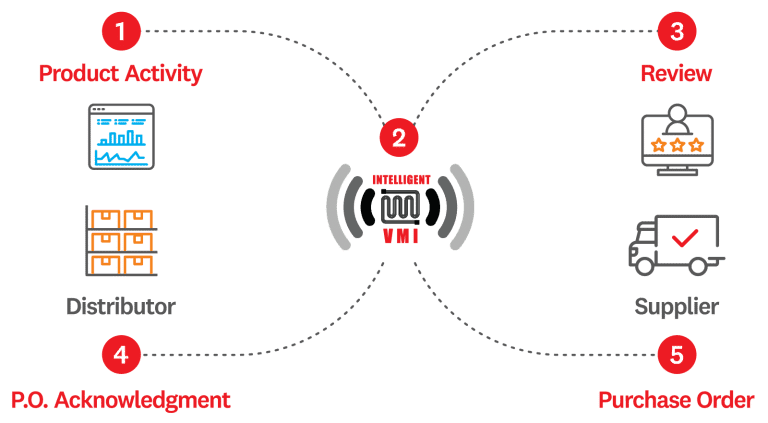

Bison Bag has worked with Anderson & Vreeland for more than 13 years and has cultivated a deep relationship together. Currently, Anderson & Vreeland supplies Bison Bag with 3M Mounting Tapes, End Seals, Doctor Blades, and other consumable resources. When Anderson & Vreeland introduced RFID, Vendor-Managed Inventory, Bison Bag was one of the first to recognize the potential of this pioneering solution. With the use of this technology, Anderson & Vreeland can monitor Bison Bag’s inventory needs based on Cloudflow data management and historical inventory trends.

Bison Bag has worked with Anderson & Vreeland for more than 13 years and has cultivated a deep relationship together. Currently, Anderson & Vreeland supplies Bison Bag with 3M Mounting Tapes, End Seals, Doctor Blades, and other consumable resources. When Anderson & Vreeland introduced RFID, Vendor-Managed Inventory, Bison Bag was one of the first to recognize the potential of this pioneering solution. With the use of this technology, Anderson & Vreeland can monitor Bison Bag’s inventory needs based on Cloudflow data management and historical inventory trends.

In September 2020, Bison Bag started using RFID to manage its inventory. According to Steve Mead, Printing Supervisor of Bison Bag, the laborious task of inventory management has been cut down with this new technology. “We used to have to do inventory management manually by printing lists of all the items that we get, checking everything weekly, and emailing A&V with a list of what we lack… With RFID technology, A&V automatically runs a report and sees what I need based on how much inventory we have on hand.” With the introduction of RFID technology into the Bison Bag workflow, they are seeing reduced transaction costs, eliminated maverick spending and increased inventory efficiencies.

Ease of Use

The RFID software’s reporting module shows Bison Bag’s real-time assessment of their inventory status. This allows for Bison Bag to better manage inventory levels, reduce shipping costs through combined shipments, free up space in their warehouse, and focus more on their business needs. “The important part of [RFID] is that it’s not managed by a person, it is an automated system. If I’m not here or busy, the inventory management is still going to get done. I don’t need to worry about things running out,” states Steve. The A&V system utilizes technology through IIoT (Industrial Internet of Things) to fully automate the client’s total cost of transaction. This ROI is realized through the reduction of labor, administrative cost, decreased stockouts and optimized fulfillment.

The software reads the RFID tags continuously to provide real-time inventory analysis. This allows Steve to track usage of the consumables on their rack on a daily, weekly and monthly basis. Additionally, he can modify the minimum and maximum quantities for each item, based on Bison’s upcoming production schedule, enabling Anderson & Vreeland to accurately forecast, with Bison Bag, to ensure their future business needs are met ahead of time.

According to Robert Feyre, Account Manager of A&V, “To compete successfully in today’s fast-paced flexographic industry, you must achieve the highest degree of inventory accuracy. To maximize profits, you must slash stock-outs, eliminate maverick spending, and reduce time spent on inventory counts and receiving. At Anderson & Vreeland we are here to help you achieve this so you can get back to what you do best!”

Continued Partnership With A&V

Bison Bag continues to stay on the cutting edge thanks to Anderson & Vreeland. “Anything new that A&V knows about that’s in the market, they’ll let us know about it. It may or may not work for us but it’s all nice to know that they are bringing in the products to my attention so we could try them out,” says Steve. With the latest RFID technology, Bison Bag streamlines their processes and operations, allowing them to become more efficient and productive.

Bison Bag has been a highly esteemed partner of Anderson & Vreeland for many years, and we are excited to continue working closely with them in optimizing their workflow.

To learn more about our Vendor-Managed Inventory solution:

- read the following article: RFID and the Path to Smart Inventory Control

- contact us for more information