Alpine’s Successful Transition

“Having both flexo and inkjet presses, we are able to decide which is most appropriate for a customer’s needs. That may be long runs on our flexo press or shorter runs with variable content on the Screen Truepress Jet L350UV inkjet press,” explains Jan Lehigh. “No matter which press we use our customers know the quality will be what they need. They are very pleased.”

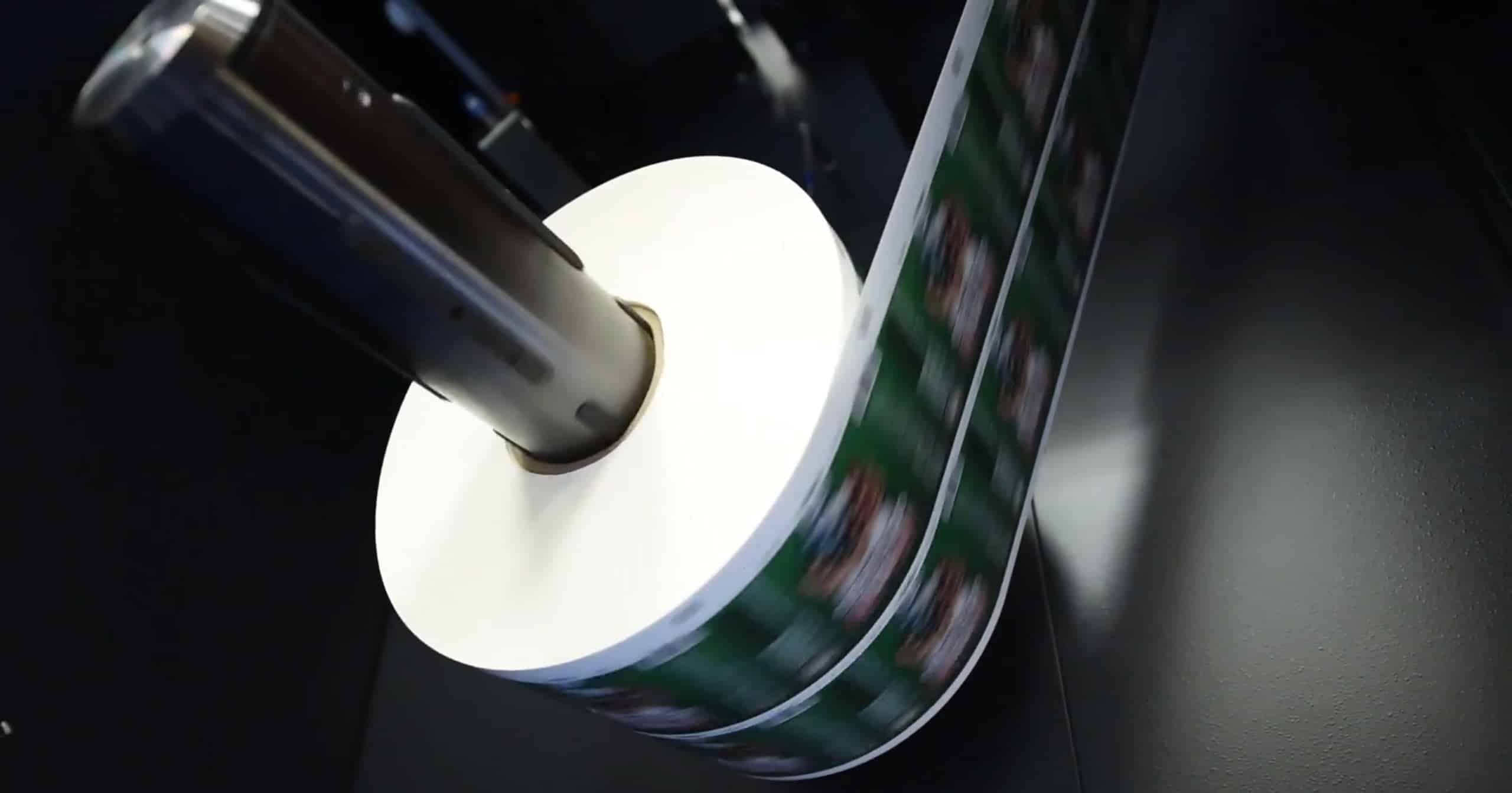

Lehigh, President of Alpine Packaging in North Versailles, Pennsylvania, put the Screen Truepress Jet L350UV into operation in the fall of 2016 and has not looked back. Not only is the press offering new label printing options for existing customers, it is opening doors to new business.

Lehigh, President of Alpine Packaging in North Versailles, Pennsylvania, put the Screen Truepress Jet L350UV into operation in the fall of 2016 and has not looked back. Not only is the press offering new label printing options for existing customers, it is opening doors to new business.

“We’re doing more wine labels, and craft beers are popping up every time you turn around. One of the big things we’re finding is tea.” She laughs. “It’s really exciting; there are so many teas reaching the market these days.” And, they all need labels as new companies build their brands.

Whether using its flexo press or the Screen L350UV, Alpine makes an effort to understand the applications for each label and what the label is being applied to so Alpine can use the right substrate and adhesive.

“For instance, we have five different adhesives for high gloss substrates, and it’s important to use the one that matches the customer’s needs,” says Lehigh. “We really consider ourselves to be ‘label engineers,’ and being able to print on both flexo and inkjet presses gives us more flexibility and is opening doors for us.”

<h2

One important addition is turning out to be variable data. On one hand, customers are asking for bar coding and versioning, sometimes related to test runs and SKU expansion. But variable content is also helping Alpine’s internal operations. The company is in the process of a “5S,” a Japanese organizational system that helps work be performed efficiently, effectively, and safely. The system focuses on putting everything where it belongs and keeping workplaces clean, making it easier for people to do their jobs without wasting time or risking injury. The 5S watchwords (in English) are Sort, Set in order, Shine, Standardize and Sustain. And it turns out that labeling is an important part of the process, giving the Screen inkjet press a key role in streamlining Alpine’s operation.

“There are about 2,000 dies, all of which require labels, plus many other items and containers that need variable data labels to work within the 5S system. We were manually printing the labels, but now with the help of our IT person the data can be pulled directly from our IT system and the labels can be run with variable data.”

Looking back, Lehigh notes that when they were limited to flexography her company was turning some short-run business away. “We kept track of who was calling and once we had the Screen press we were able to go back and let them know we could help them out.”

“And now we are. We find many customers are increasingly eager to take advantage of shorter run lengths,” exclaims Lehigh. “It’s amazing!”