- About

- Portfolio

- Pre-Press

- Plateroom

- Pressroom

- Anilox Rolls

- Cleaning Products

- Corrugated Applications

- Doctor Blades & End Seals

- Ergonomic Lifters

- Material Handling

- Miscellaneous Pressroom Supplies

- Mounting Tapes

- Plate Cutting

- Plate Mounters

- Plate/Sleeve Storage

- Powerwise Ink Pumps and Accessories

- Sleeves

- Tape Applicators/Case Sealers

- Zinc/Magnesium Plate Etching Equipment

- Flexo University

- Contact

Anderson & Vreeland

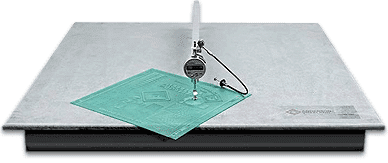

A&V Bench Micrometers

A&V digital plate micrometers are designed to measure flexo plates in thicknesses up to 1.0″/25.4 mm at a resolution up... Read More →

A&V Cleaning Solutions and Supplies

Anilox Cleaners AV Anilox Cleaner Premium cleaner be used in FlexoWash anilox cleaners, cut 50/50 with water; cleans UV, UV-LED,... Read More →

A&V Flexo Plate Washer

A&V 110 x 66 Flexo Plate Washer Flexo Printing Plate Washer Extends Plate Life The Flexo Plate Washer is... Read More →

A&V Tabletop Mounter 7800

Mount Narrow Web Plates from 8″ to 16″ The Mounter 7800 is a compact, tabletop unit designed to mount narrow... Read More →

A&V Tape Carousel

Organize, store and conveniently access plate mounting tape at your fingertips with an A&V tape carousel. The 6-roll tape carousel... Read More →

A&V Xpose Unit

Exposure Unit Exposure unit designed for digital imaging and the thermal market. Available in 2 sizes: 25″x30″ (2530 model) and... Read More →

Model 77 Sleeve Demounter

Delaminate Mounted Printing Plates from Sleeves Our model 77 Sleeve Plate Demounter is designed to delaminate mounted printing plates from... Read More →

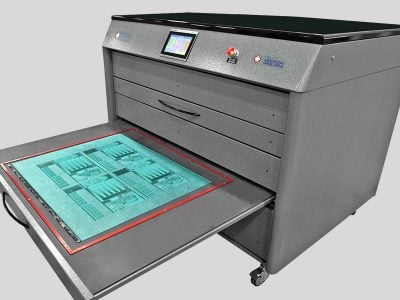

Orbital X Processor

Water-Wash Photopolymer Plate Processors Anderson & Vreeland offers a complete selection of water-wash photopolymer plate processors that are good for... Read More →