Screen USA Packaging Solutions

Anderson & Vreeland Now Offers Screen USA Packaging Solutions in North America.

With its appointment as a distributor of Screen USA packaging solutions throughout North America, Anderson & Vreeland now offers a unique combination of digital imaging systems, integrated workflows and inkjet printers designed for flexo applications.

“Screen’s packaging solutions will complement our innovative line-up of best-in-class products for flexo and letterpress, so we can serve a broader range of applications and markets,” noted Lee Zerfass, Digital Business Manager for Anderson & Vreeland. “As we look to the future A&V will continue to introduce technical innovation and forward-thinking solutions,” added Zerfass.

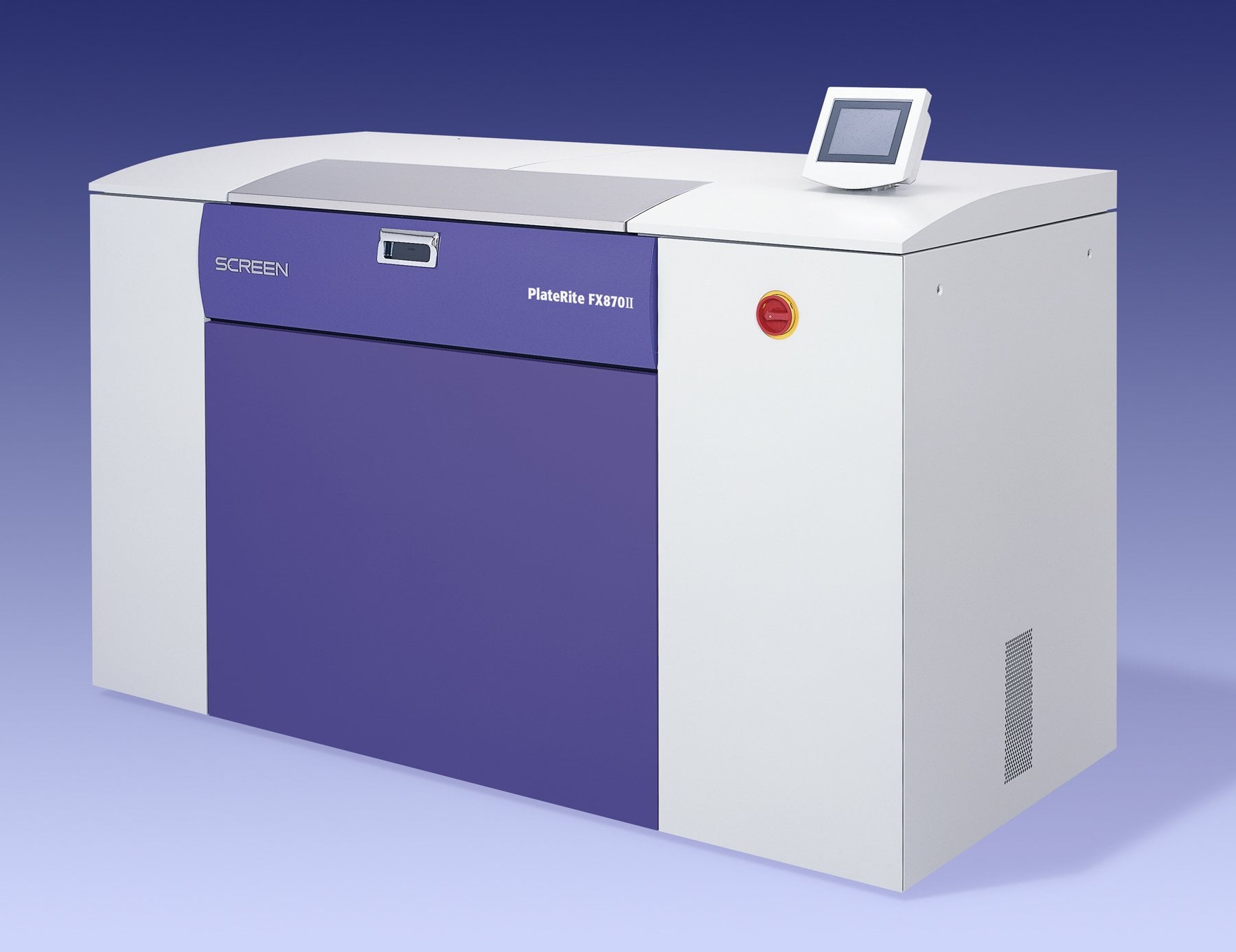

Screen USA packaging solutions include the PlateRite FX series of innovative digital imagers specifically designed to improve quality and productivity while reducing the cost of flexo and letterpress platemaking. Ease of operation and consistent high-quality plate output are key features of the PlateRite FS Series that incorporate proven laser imaging technology to produce plates at resolutions up to 4,800 dpi.

EQUIOS Flexo Series is a key component of Screen’s integrated plate production solutions with complete JDF and PDF capabilities for flexo and letterpress printing. EQUIOS Flexo Series streamlines print management and simplifies the production workflow providing increased efficiency.

Screen’s Truepress Jet L350UV inkjet printer complements Screen’s innovative digital imagers and workflows by delivering photo-realistic quality, stable output and fast turn-around on short-to-medium run printing applications.

Eduardo “Wadie” Navarro, Screen’s manager of marketing and CTP/flexo products, said “A&V’s strong sales and service organization, combined with its extensive knowledge of flexographic printing, are important strengths that will help expand our production-enhancing packaging solutions in North America.”

Anderson & Vreeland will sell Screen USA packaging solutions and provide technical support using a nationwide staff of technical sales representatives. For more information visit www.AndersonVreeland.com or call toll-free 866.282.7697.

About Anderson & Vreeland, Inc.

Founded in 1961, Anderson & Vreeland has earned an international reputation as a leading provider of flexo prepress solutions for the graphic arts industry. The company offers a “systems” approach to conducting business by evaluating customer needs and offering the best solutions in the form of equipment, materials, training, and technology tailored for each customer. A&V supports these solutions with over 50 years of experience and a staff of technical sales representatives thoroughly knowledgeable about the fine points of flexo. The company’s substantial flexo experience and technical support sets it apart from other prepress suppliers. This experience and support results in smoother and easier integration of technical advancements affecting flexo prepress. Further information is available on the web at www.AndersonVreeland.com.